Product Description

Our advantage:

*Specialization in CNC formulations of high precision and quality

*Independent quality control department

*Control plan and process flow sheet for each batch

*Quality control in all whole production

*Meeting demands even for very small quantities or single units

*Short delivery times

*Online orders and production progress monitoring

*Excellent price-quality ratio

*Absolute confidentiality

*Various materials (stainless steel, iron, brass, aluminum, titanium, special steels, industrial plastics)

*Manufacturing of complex components of 1 – 1000mm.

Production machine:

| Specification | Material | Hardness |

| Z13 | Steel | HRC35-40 |

| Z16 | Steel | HRC35-40 |

| Z18 | Steel | HRC35-40 |

| Z20 | Steel | HRC35-40 |

| Z26 | Steel | HRC35-40 |

| Z28 | Steel | HRC35-40 |

| Custom dimensions according to drawings | Steel | HRC35-40 |

Production machine:

Inspection equipment :

Gear tester

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Steel |

| Customization: |

Available

| Customized Request |

|---|

How do you install a bevel gear system?

Installing a bevel gear system involves several steps to ensure proper alignment, smooth operation, and efficient power transmission. Here’s a detailed explanation of how to install a bevel gear system:

- Preparation: Before installing the bevel gear system, gather all the necessary tools and equipment. Ensure that you have the correct bevel gears, shafts, bearings, and any additional components required for your specific application. Familiarize yourself with the system’s design, specifications, and installation instructions provided by the gear manufacturer.

- Clean and Inspect: Thoroughly clean all the components of the bevel gear system, including the gears, shafts, and bearings. Inspect them for any signs of damage, wear, or defects. Replace any damaged or worn-out parts to ensure optimal performance and longevity.

- Shaft Alignment: Proper alignment of the shafts is crucial for the bevel gear system’s performance. Ensure that the shafts are aligned accurately, both angularly and axially, as specified by the manufacturer. Misalignment can lead to premature wear, increased noise, and reduced efficiency. Use precision measurement tools, such as dial indicators, to achieve the required alignment.

- Bearing Installation: Install the bearings on the shafts according to the manufacturer’s instructions. Ensure that the bearings are securely fitted and properly lubricated. Proper bearing installation helps support the shafts, reduces friction, and ensures smooth rotation of the gears.

- Gear Meshing: Carefully position the bevel gears on the shafts, ensuring proper meshing between the teeth. The gear teeth should engage smoothly and evenly without any binding or excessive clearance. Achieving the correct gear meshing is crucial for efficient power transmission and to prevent premature wear or damage to the gears.

- Housing Assembly: Assemble the housing or casing that encloses the bevel gear system. Ensure that all housing components are aligned and securely fastened. Follow the manufacturer’s instructions for proper housing assembly, including the use of gaskets or seals to prevent lubricant leakage and contamination.

- Lubrication: Proper lubrication is essential for the smooth operation and longevity of the bevel gear system. Apply the recommended lubricant to the gears, bearings, and other moving parts according to the manufacturer’s specifications. Ensure that the lubricant used is compatible with the gear material, operating conditions, and environmental factors.

- Testing and Adjustment: After the installation is complete, perform a thorough system check. Rotate the shafts manually or using a suitable drive mechanism to ensure smooth gear operation, proper alignment, and absence of abnormal noise or vibration. Make any necessary adjustments, such as gear backlash or meshing depth, as per the manufacturer’s guidelines and based on the specific application requirements.

It’s important to note that the installation process may vary depending on the specific bevel gear system and application. Always refer to the manufacturer’s instructions and guidelines for the particular gear system you are working with to ensure proper installation and optimal performance.

In summary, installing a bevel gear system involves preparation, cleaning and inspection, shaft alignment, bearing installation, gear meshing, housing assembly, lubrication, and thorough testing and adjustment. Following proper installation procedures and adhering to manufacturer guidelines are essential to achieve efficient power transmission, smooth operation, and the desired performance from the bevel gear system.

How do you retrofit an existing mechanical system with a bevel gear?

Retrofitting an existing mechanical system with a bevel gear involves modifying the system to incorporate the bevel gear for improved functionality or performance. Here’s a detailed explanation of the retrofitting process:

- Evaluate the Existing System: Begin by thoroughly evaluating the existing mechanical system. Understand its design, components, and operational requirements. Identify the specific areas where the introduction of a bevel gear can enhance the system’s performance, efficiency, or functionality.

- Analyze Compatibility: Assess the compatibility of the existing system with the integration of a bevel gear. Consider factors such as available space, load requirements, torque transmission, and alignment feasibility. Determine if any modifications or adaptations are necessary to accommodate the bevel gear.

- Design Considerations: Based on the system evaluation and compatibility analysis, develop a design plan for incorporating the bevel gear. Determine the appropriate gear type, size, and configuration that best suits the retrofitting requirements. Consider factors such as gear ratio, torque capacity, tooth profile, and mounting options.

- Modify Components: Identify the components that need modification or replacement to integrate the bevel gear. This may involve machining new shafts or shaft extensions, modifying housing or mounting brackets, or adapting existing components to ensure proper alignment and engagement with the bevel gear.

- Ensure Proper Alignment: Proper alignment is crucial for the successful integration of the bevel gear. Ensure that the existing system components and the bevel gear are aligned accurately to maintain smooth and efficient power transmission. This may involve adjusting shaft positions, aligning bearing supports, or employing alignment fixtures during the retrofitting process.

- Lubrication and Sealing: Consider the lubrication requirements of the bevel gear system. Ensure that appropriate lubricants are selected and provisions for lubrication are incorporated into the retrofit design. Additionally, pay attention to sealing arrangements to prevent lubricant leakage or ingress of contaminants into the gear system.

- Testing and Validation: After the retrofitting process is complete, conduct thorough testing and validation of the modified mechanical system. Ensure that the bevel gear functions as intended and meets the desired performance requirements. Perform functional tests, load tests, and monitor the system for any abnormalities or issues.

- Maintenance and Documentation: Develop a maintenance plan for the retrofitted system, including periodic inspection, lubrication, and any specific maintenance tasks related to the bevel gear. Document the retrofitting process, including design modifications, component specifications, alignment procedures, and any other relevant information. This documentation will be valuable for future reference, troubleshooting, or potential further modifications.

Retrofitting an existing mechanical system with a bevel gear requires careful planning, engineering expertise, and attention to detail. It is recommended to involve experienced gear engineers or professionals with expertise in retrofitting processes to ensure a successful integration and optimal performance of the bevel gear within the system.

By retrofitting an existing mechanical system with a bevel gear, it is possible to enhance its capabilities, improve efficiency, enable new functionalities, or address specific performance issues. Proper analysis, design, and implementation are essential to achieve a successful retrofit and realize the desired benefits of incorporating a bevel gear into the system.

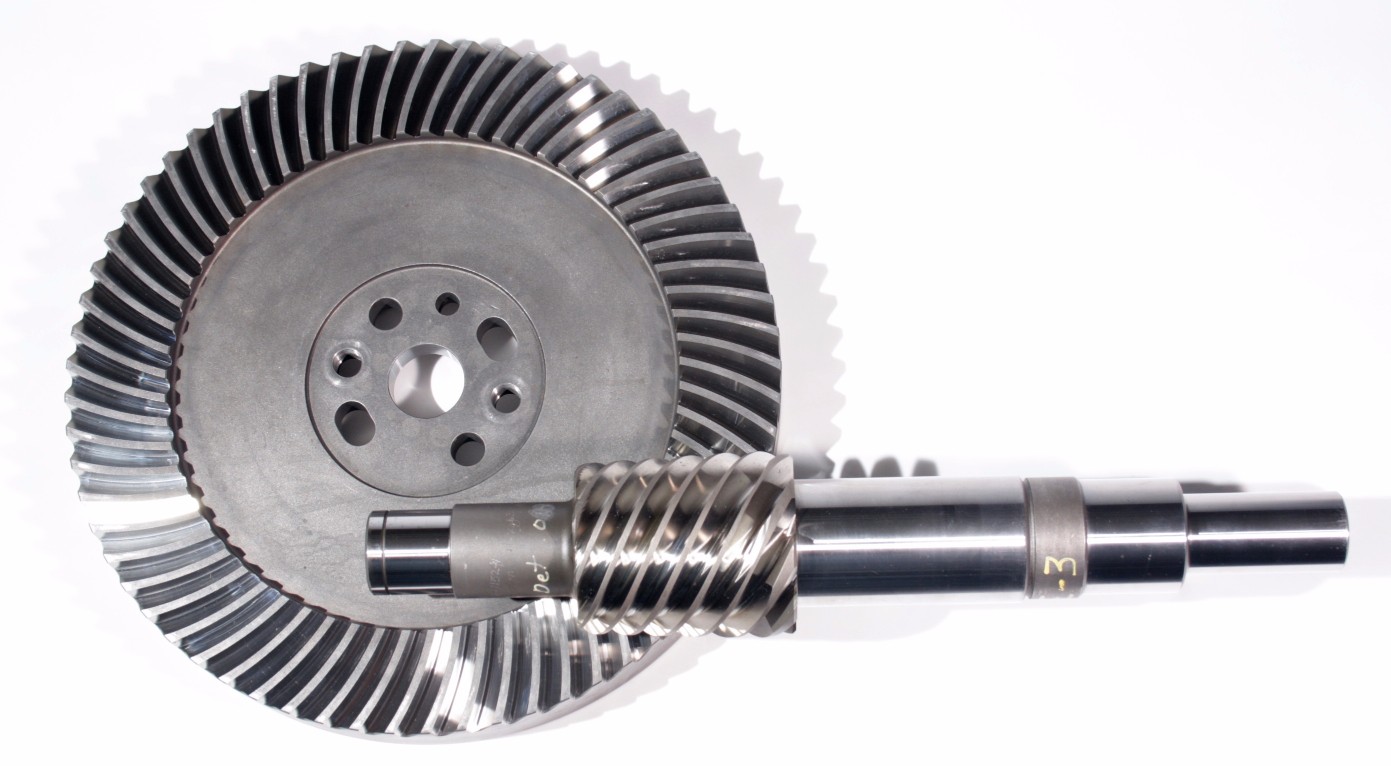

What is a bevel gear and how does it work?

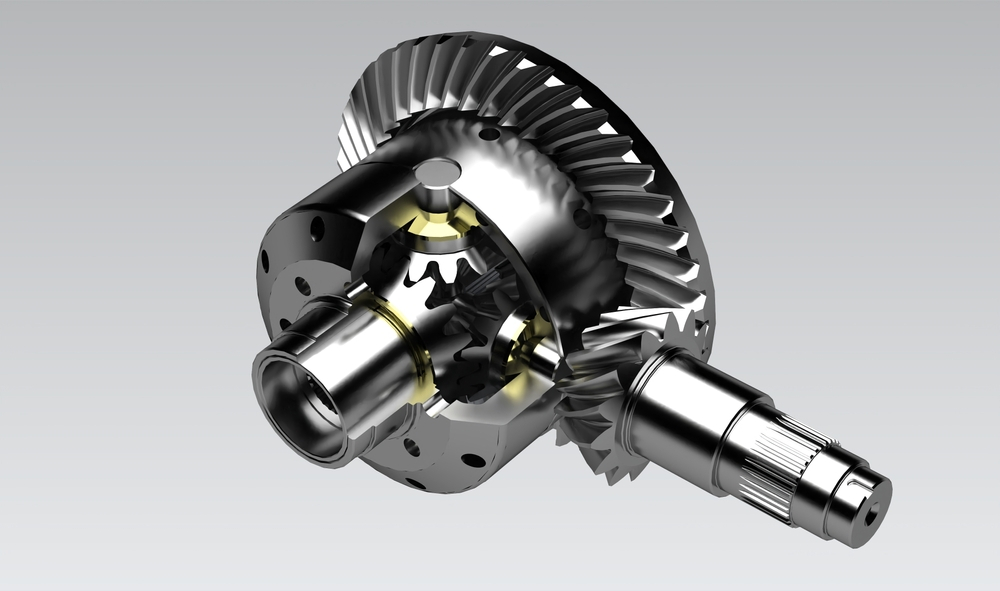

A bevel gear is a type of gear that has teeth cut on the cone-shaped surface of the gear. It is used to transmit rotational motion and power between two intersecting shafts. Here’s a detailed explanation of what a bevel gear is and how it works:

A bevel gear consists of two cone-shaped gears with intersecting axes. The gear teeth are cut on the tapered surface of the gears. The gear with the smaller diameter is called the pinion, while the gear with the larger diameter is called the crown gear or ring gear.

Bevel gears are classified into different types based on their tooth geometry and arrangement. The most common types are straight bevel gears, spiral bevel gears, and hypoid bevel gears. Straight bevel gears have straight-cut teeth and intersect at a 90-degree angle. Spiral bevel gears have curved teeth that are gradually cut along the gear surface, allowing for smoother engagement and reduced noise. Hypoid bevel gears have offset axes and are used when the intersecting shafts are non-parallel.

When two bevel gears mesh together, the rotational motion from one gear is transmitted to the other gear. The gear teeth engage and disengage as the gears rotate, transferring torque and power between the shafts.

The operation of bevel gears is similar to that of other types of gears. When the pinion gear rotates, it causes the crown gear to rotate in the opposite direction. The direction of rotation can be reversed by changing the orientation of the gears. Bevel gears can provide different speed ratios and torque conversions depending on the gear sizes and the number of teeth.

The key characteristics of bevel gears include:

- Transmission of motion: Bevel gears are used to transmit rotational motion between intersecting shafts, allowing for changes in direction and speed.

- Torque transfer: Bevel gears can transmit torque from one shaft to another, allowing for power transmission in various mechanical systems.

- Axial thrust: Due to the angled tooth arrangement, bevel gears generate axial thrust forces that need to be properly supported or accounted for in the design of the mechanical system.

- Efficiency and noise: The efficiency and noise characteristics of bevel gears depend on factors such as tooth design, lubrication, and manufacturing quality.

Bevel gears are commonly used in a wide range of applications, including automotive differentials, power tools, printing presses, machine tools, and marine propulsion systems. Their ability to transmit motion and torque at intersecting angles makes them versatile and suitable for various mechanical systems.

In summary, a bevel gear is a cone-shaped gear that transmits rotational motion and power between intersecting shafts. It works by meshing the gear teeth of two gears, allowing for the transfer of torque and rotational motion. Bevel gears are available in different types and are used in various applications that require changes in direction or speed of rotational motion.

editor by Dream 2024-05-06

China Professional Gear Specialized Vendor High OEM Double Helical Spur Plastic Gear for Gear Box Motor raw gear

Product Description

Product Description

|

Item |

Gear specialized vendor high OEM Double helical spur plastic gear for gear box motor |

|

Material |

ABS, PC/ABS, PP, PC, POM(Delrin), Nylon 6, Nylon 6/6, PA 12, HDPE, LDPE, PS(HIPS), SAN/AS, ASA, PVC, UPVC, TPE, TPR, PU, TPU, PET, PEI(Ultem), PSU, PPSU, PPE/PS, PTFE, GPPS, PPO, PES, CA, etc |

|

Certificate |

IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /REACH/ROHS/MSDS/LFGB/F D A |

|

Drawing Format |

.stp / .step / .igs /.CHINAMFG /.dwg / .pdf |

|

Color |

Almost all PMS colors available. |

|

Parameters |

Inch, centimeter, millimeter, etc. |

|

Function |

Industrial parts /daily supply / Medical grade supply, etc. |

|

Surface Treatment |

Matte, Common polishing, Mirror polishing, Texture, Plating, Power Coating (Painting), Laser Engraving, Brushing, Marbling, Printing etc. |

|

Mold Material |

S136H, 718H, NAK80, P20, H13, etc. |

|

Mold Precision |

If no special request, apply to SJ/T10628-1995 standards, class 3. |

|

Mold Life-cycle |

100,000-500,000 shots. |

|

Packing |

Pack in bulk / poly bag / bubble bag / color box. |

|

Sample |

Available. One cavity sample mold or 3D printing. |

|

Price Tip |

The price shown above is just for reference, final actual price depends on your design, material request, surface treatment, order qty, package request, etc. |

Gear specialized vendor high OEM Double helical spur plastic gear for gear box motor

1. Rapid Prototyping & On-demand production services;

2. Professional DFM Report before Mould Making;

3.Capability for Plastic Injection Molding is up to 1500mm

DFM Report (Design for Manufacturability) for Reference.

Some Custom CHINAMFG & Moulds for Your Reference.

Neway Highly Welcome Your Own Custom Designs !!!

Neway Support Custom Design Moulds & Moulds Export.

Neway Can Also Provide Mould Spare Parts Export, eg: Slider, Inserts, Ejector Pins, etc.

NEWAY has complete production chain from R&D, Rapid Prototypes, mould design, mould making, components production, assembling, packing to export. Having 1 supplier like CHINAMFG for the complete assembly will allow for better design, quality, and fit of all the individual parts.

The most common used surface treatment are: Matte, Texture (fine texture, rough texture…), Common Polishing, Mirror Polishing, Laser Engraving, Printing, Plating, Brushing, Marbling), etc. You can view below surface pictures for reference

Company Profile

Our Advantages

Good reviews of customer

Certifications

Below are some inspection equipment for reference:

And attach the injection molding CHINAMFG inspection report for reference:

Packaging & Shipping

FAQ

Q1. How soon can I get a precise quotation for custom plastic injection part?

A1: Please send us your inquiry by email or Alibaba TM message. Once we confirm the design (Feature details with parameters), material, color, qty, we can provide quotation within 24 HOURS.

Q2: Can I get a free sample, how long will it take?

A2: a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance.

Mostly, it takes 3-10 days.

b. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.

Q3: Can you make custom parts based on my sample?

A3: Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for production.

Q4: What does your OEM service include?

A4: We follow up your request from the design idea to the mass production.

a. You can provide 3D drawing to us, then our engineers and production teams evaluate the design and quote you the precise cost.

b. If you don’t have 3D drawing, you can provide 2D drawing or draft with features details with full dimensions, we can draft 3D drawing for you with fair charge.

c. You can also customize Logo on the product surface, package, color box or carton.

d. We also provide assembly service for the OEM parts.

Q5. What is your payment term?

A5: We accept T/T, Paypal, Western Union, L/C, Alibaba Trade Assurance.

Work with Neway, your business is in safe and your money is in safe!

If you can dream it, we can build it!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Toothed Portion Shape: | Bevel Wheel |

| Material: | Plastic |

| Type: | Bevel Gear |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do you calculate the efficiency of a spur gear?

Calculating the efficiency of a spur gear involves considering the power losses that occur during gear operation. Here’s a detailed explanation:

In a gear system, power is transmitted from the driving gear (input) to the driven gear (output). However, due to various factors such as friction, misalignment, and deformation, some power is lost as heat and other forms of energy. The efficiency of a spur gear represents the ratio of the output power to the input power, taking into account these power losses.

Formula for Calculating Gear Efficiency:

The efficiency (η) of a spur gear can be calculated using the following formula:

η = (Output Power / Input Power) × 100%

Where:

η is the efficiency of the gear system expressed as a percentage.

Output Power is the power delivered by the driven gear (output) in the gear system.

Input Power is the power supplied to the driving gear (input) in the gear system.

Factors Affecting Gear Efficiency:

The efficiency of a spur gear is influenced by several factors, including:

- Tooth Profile: The tooth profile of the gear affects the efficiency. Well-designed gear teeth with accurate involute profiles can minimize friction and power losses during meshing.

- Lubrication: Proper lubrication between the gear teeth reduces friction, wear, and heat generation, improving gear efficiency. Insufficient or inadequate lubrication can result in increased power losses and reduced efficiency.

- Gear Material: The selection of gear material affects efficiency. Materials with low friction coefficients and good wear resistance can help minimize power losses. Higher-quality materials and specialized gear coatings can improve efficiency.

- Gear Alignment and Meshing: Proper alignment and precise meshing of the gear teeth are essential for optimal efficiency. Misalignment or incorrect gear meshing can lead to increased friction, noise, and power losses.

- Bearing Friction: The efficiency of a gear system is influenced by the friction in the bearings supporting the gear shafts. High-quality bearings with low friction characteristics can contribute to improved gear efficiency.

- Load Distribution: Uneven load distribution across the gear teeth can result in localized power losses and reduced efficiency. Proper design and gear system configuration should ensure even load distribution.

Interpreting Gear Efficiency:

The calculated gear efficiency indicates the percentage of input power that is effectively transmitted to the output. For example, if a gear system has an efficiency of 90%, it means that 90% of the input power is converted into useful output power, while the remaining 10% is lost as various forms of power dissipation.

It’s important to note that gear efficiency is not constant and can vary with operating conditions, lubrication quality, gear wear, and other factors. The calculated efficiency serves as an estimate and can be influenced by specific system characteristics and design choices.

By considering the factors affecting gear efficiency and implementing proper design, lubrication, and maintenance practices, gear efficiency can be optimized to enhance overall gear system performance and minimize power losses.

What is the purpose of using spur gears in machinery?

In machinery, spur gears serve several important purposes due to their unique characteristics and capabilities. Here’s a detailed explanation of the purpose of using spur gears in machinery:

- Power Transmission: Spur gears are primarily used for power transmission in machinery. They transfer rotational motion and torque from one shaft to another, allowing machinery to perform various tasks. By meshing the teeth of two or more spur gears together, power can be transmitted efficiently and reliably throughout the machinery.

- Speed Reduction or Increase: Spur gears enable speed reduction or increase in machinery. By combining gears with different numbers of teeth, the rotational speed can be adjusted to match the desired output speed. For example, using a larger gear driving a smaller gear can increase the speed output while reducing the torque, while the opposite arrangement can decrease the speed while increasing the torque.

- Torque Amplification: Spur gears can amplify torque in machinery. By using gears with different numbers of teeth, the torque can be adjusted to match the required output. For example, using a smaller gear driving a larger gear can increase the torque output while reducing the speed, while the opposite arrangement can decrease the torque while increasing the speed.

- Directional Control: Spur gears provide directional control in machinery. By meshing gears with opposite orientations, the rotational direction of the driven shaft can be reversed or changed. This directional control is crucial for machinery that requires bi-directional motion or needs to change the direction of operation.

- Mechanical Advantage: Spur gears offer a mechanical advantage in machinery. By utilizing gear ratios, spur gears can multiply or divide the force exerted on the input shaft. This mechanical advantage allows machinery to generate higher forces or achieve precise movements with reduced effort.

- Precision Positioning: Spur gears facilitate precise positioning in machinery. The accurate tooth engagement of spur gears ensures precise control over rotational motion, making them suitable for applications that require precise positioning or synchronization of components. Machinery such as CNC machines, robotics, and automation systems often rely on spur gears for accurate movement and positioning.

- Compact Design: Spur gears have a compact design, making them suitable for machinery with space constraints. They can be arranged in-line, parallel, or at right angles, allowing for efficient power transmission in tight spaces. Their compactness enables machinery to be designed with smaller footprints and optimized layouts.

- Reliability and Durability: Spur gears are known for their reliability and durability in machinery. The direct tooth engagement and uniform load distribution result in efficient power transmission with reduced wear and stress concentration. When properly lubricated and maintained, spur gears can withstand heavy loads and operate reliably over extended periods.

- Cost-Effectiveness: Spur gears are often cost-effective in machinery applications. Their simple design and ease of manufacturing contribute to lower production costs. Additionally, their high efficiency helps reduce energy consumption, resulting in potential long-term cost savings. The availability of spur gears in various sizes and materials further enhances their cost-effectiveness.

By utilizing spur gears in machinery, engineers and designers can achieve efficient power transmission, speed and torque control, directional versatility, mechanical advantage, precise positioning, compact design, reliability, durability, and cost-effectiveness. These advantages make spur gears a popular choice in a wide range of machinery applications across industries.

Are there different sizes and configurations of spur gears available?

Yes, there are various sizes and configurations of spur gears available to suit different applications and requirements. Here’s a detailed explanation of the different options when it comes to sizes and configurations of spur gears:

Sizes: Spur gears come in a wide range of sizes to accommodate different torque and speed requirements. The size of a spur gear is typically specified by its pitch diameter, which is the diameter of the pitch circle. The pitch diameter determines the gear’s overall size and the spacing between the teeth. Spur gears can range from small gears used in precision instruments to large gears used in heavy machinery and industrial equipment.

Module: Module is a parameter used to specify the size and spacing of the teeth on a spur gear. It represents the ratio of the pitch diameter to the number of teeth. Different module sizes are available to accommodate various gear sizes and applications. Smaller module sizes are used for finer tooth profiles and higher precision, while larger module sizes are used for heavier loads and higher torque applications.

Number of Teeth: The number of teeth on a spur gear can vary depending on the specific application. Gears with a higher number of teeth provide smoother operation and distribute the load more evenly, whereas gears with fewer teeth are typically used for higher speeds and compact designs.

Pressure Angle: The pressure angle is an important parameter that determines the shape and engagement of the teeth. Common pressure angles for spur gears are 20 degrees and 14.5 degrees. The selection of the pressure angle depends on factors such as load capacity, efficiency, and specific design requirements.

Profile Shift: Profile shift is a design feature that allows modification of the tooth profile to optimize the gear’s performance. It involves shifting the tooth profile along the gear’s axis, which can affect factors such as backlash, contact ratio, and load distribution. Profile shift can be positive (when the tooth profile is shifted towards the center of the gear) or negative (when the tooth profile is shifted away from the center).

Hub Configuration: The hub refers to the central part of the gear where it is mounted onto a shaft. Spur gears can have different hub configurations depending on the specific application. Some gears have a simple cylindrical hub, while others may have keyways, set screws, or other features to ensure secure and precise mounting.

Material and Coatings: Spur gears are available in various materials to suit different operating conditions and requirements. Common materials include steel, cast iron, brass, and plastic. Additionally, gears can be coated or treated with surface treatments such as heat treatment or coatings to enhance their wear resistance, durability, and performance.

Mounting Orientation: Spur gears can be mounted in different orientations depending on the application and space constraints. They can be mounted parallel to each other on parallel shafts, or they can be mounted at right angles using additional components such as bevel gears or shafts with appropriate bearings.

In summary, there is a wide range of sizes and configurations available for spur gears, including different pitch diameters, module sizes, number of teeth, pressure angles, profile shifts, hub configurations, materials, coatings, and mounting orientations. The selection of the appropriate size and configuration depends on factors such as torque requirements, speed, load capacity, space constraints, and specific application needs.

editor by Dream 2024-05-06

China Good quality Customized Gear Rack Bevel Gear Sprocket Chain Coupling Worm Synchronous Gear Brass Worm Wheels Gear for Transmission Parts worm gearbox

Product Description

Item:Customized gear rack bevel gear sprocket chain coupling worm synchronous gear Brass Worm Wheels Gear for Transmission Parts

1. High degree of automation and high production efficiency;

2. Strong adaptability to CNC machining objects. When changing the processing object, in addition to replacing and solving the blank clamping mode, it only needs to be reprogrammed;

3. High machining precision and stable quality. The machining dimensional accuracy is between 0.005 ~ 0.01 mm, which is not affected by the complexity of parts;

Parameter :

| Item | Customized gear rack bevel gear sprocket chain coupling worm synchronous gear Brass Worm Wheels Gear for Transmission Parts |

| Weight | Customized |

| Dimension | Customized |

| Material | Aluminum alloy(6063 T5,6061,5052,7075,1060…),Stainless steel(316L,304,303…),Copper,Brass,Bronze,Carbon steel,PET,POM,Nylon… |

| Machined Technology | 3,4,5 Axis CNC Machining,CNC Milling,CNC Turning,Laser Cutting,Die Casting,Cold forging,Aluminum Extrusion,Sheet Metal Fabrication,Stamping,Welding,Friction Stir Welding,Assembling. |

| Surface Treatment | Anodizing,Painting,Powder Coating,electrophoresis,Passivation,Sand Blasting,Plating,Blackening,Polishing… |

| Tolerance | ±0.01MM |

| Application | Electronic products body ,Telecom Chasis,Cover,aerospace structure parts,heat sink,aluminum cooling plate,gear&shaft,bearing,high speed feed through,other OEM/ODM customized machining parts |

Our advantage:

1. Experienced engineering team;

2. Full process QC inspection, complete quality system before, during and after processing;

3. Efficient and rapid response, benign interaction between business and production, and accurately grasp customer requirements;

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Are bevel gears suitable for high-torque applications?

Bevel gears can indeed be suitable for high-torque applications, depending on various factors such as the specific design, material selection, and proper application engineering. Here’s a detailed explanation:

Bevel gears are known for their ability to transmit power between intersecting shafts at different angles. They can handle significant torque loads and are commonly used in applications that require high-torque transmission. However, the suitability of bevel gears for high-torque applications depends on the following factors:

- Design: The design of the bevel gears plays a crucial role in their ability to handle high torque. Factors such as tooth profile, size, and geometry impact the load-carrying capacity and torque transmission capability. Bevel gears with robust and optimized designs, including suitable tooth profiles and adequate tooth engagement, can effectively handle high-torque applications.

- Material Selection: The choice of materials for bevel gears is critical in high-torque applications. Gears need to be made from materials with high strength, hardness, and wear resistance to withstand the forces and stresses involved in transmitting high torque. Common materials used for bevel gears include alloy steels, carburizing steels, and specialty alloys. Material selection should consider the specific torque requirements, operating conditions, and anticipated loads to ensure the gears can handle the desired torque levels.

- Lubrication: Proper lubrication is essential for reducing friction, wear, and heat generation in high-torque bevel gear applications. Adequate lubrication helps maintain a lubricating film between the gear teeth, minimizing metal-to-metal contact and associated losses. The lubricant type, viscosity, and replenishment schedule should be selected based on the torque and operating conditions to ensure effective lubrication and minimize gear wear.

- Gear Size and Ratio: The size of the bevel gears and the gear ratio can influence their torque-handling capability. Larger gears generally have greater tooth strength and load-carrying capacity, making them more suitable for high-torque applications. The gear ratio should also be considered to ensure it is appropriate for the desired torque transmission and to avoid excessive loads on the gears.

- Operating Conditions: The operating conditions, including speed, temperature, and shock loads, must be taken into account when determining the suitability of bevel gears for high-torque applications. Higher speeds and extreme operating temperatures can affect the gear material properties, lubrication performance, and overall gear system efficiency. Proper cooling, temperature control, and gear protection measures should be implemented to maintain reliable performance under high-torque conditions.

By considering these factors and properly engineering the bevel gear system, it is possible to utilize bevel gears in high-torque applications effectively. However, it is crucial to consult with experienced engineers and perform thorough analysis and testing to ensure the gears can handle the specific torque requirements of the application.

What are the environmental considerations when using bevel gears?

When using bevel gears, there are several environmental considerations to keep in mind. These considerations encompass aspects such as material selection, lubrication, noise generation, and waste management. Here’s a detailed explanation:

1. Material Selection: The choice of materials for bevel gears can have environmental implications. Opting for environmentally friendly materials, such as recyclable or biodegradable materials, can help reduce the environmental impact. Additionally, selecting materials with low toxicity or hazardous properties contributes to safer handling and disposal practices.

2. Lubrication: Proper lubrication is essential for the efficient operation of bevel gears. However, the choice and use of lubricants can have environmental consequences. It is advisable to select lubricants that are environmentally friendly, such as biodegradable or non-toxic lubricants, to minimize the risk of contamination in case of leaks or spills. Additionally, implementing effective lubricant management practices, such as proper containment and recycling, helps reduce environmental pollution.

3. Noise Generation: Bevel gears can generate noise during operation, which can have environmental implications, especially in noise-sensitive areas or workplaces. Excessive noise can contribute to noise pollution and affect the well-being of individuals in the vicinity. Implementing noise reduction measures, such as using noise-dampening materials, optimizing gear design for quieter operation, and implementing proper maintenance practices, can help minimize noise pollution.

4. Energy Efficiency: Bevel gears are part of power transmission systems that consume energy. Considering energy efficiency in gear system design and operation can contribute to reduced energy consumption and lower environmental impact. This can be achieved by optimizing gear designs for higher efficiency, reducing friction losses through proper lubrication and surface treatments, and implementing efficient power transmission systems.

5. Waste Management: The manufacturing and maintenance processes involving bevel gears can generate waste materials, such as metal shavings, lubricant residues, or worn-out gears. Proper waste management practices, including recycling and disposal, are crucial to minimize the environmental impact. Recycling materials whenever possible and ensuring the proper disposal of hazardous or toxic waste materials are important considerations in reducing environmental pollution.

6. Life Cycle Assessment: Conducting a life cycle assessment (LCA) of bevel gears can provide a comprehensive understanding of their environmental impact. LCA takes into account the environmental implications associated with the entire life cycle of the gears, including raw material extraction, manufacturing, use, and end-of-life disposal. This assessment helps identify areas for improvement and guides decision-making towards more sustainable practices.

By considering these environmental factors, manufacturers, engineers, and users of bevel gears can make conscious choices to minimize the environmental impact associated with their production, operation, and disposal. Implementing sustainable practices and adhering to environmental regulations and standards contribute to a greener and more sustainable use of bevel gears.

How do bevel gears differ from other types of gears?

Bevel gears have distinct characteristics that set them apart from other types of gears. Here’s a detailed explanation of how bevel gears differ from other gears:

1. Tooth Geometry: Bevel gears have teeth cut on the cone-shaped surface of the gears, whereas other types of gears, such as spur gears and helical gears, have teeth cut on cylindrical surfaces. The tooth geometry of bevel gears allows them to accommodate intersecting shafts and transmit rotational motion at different angles.

2. Axis Orientation: Bevel gears have intersecting axes, meaning the shafts they are mounted on intersect each other. In contrast, other types of gears typically have parallel or skewed axes. The intersecting axis of bevel gears allows for changes in direction and allows for power transmission between shafts that are not in a straight line.

3. Types of Bevel Gears: Bevel gears come in different variations, including straight bevel gears, spiral bevel gears, and hypoid bevel gears. Straight bevel gears have straight-cut teeth and intersect at a 90-degree angle. Spiral bevel gears have curved teeth that are gradually cut along the gear surface, providing smoother engagement and reduced noise. Hypoid bevel gears have offset axes and are used when the intersecting shafts are non-parallel. Other types of gears, such as spur gears and helical gears, also have their own variations but do not typically involve intersecting axes.

4. Direction of Motion: Bevel gears can change the direction of rotational motion between intersecting shafts. Depending on the orientation of the gears, the direction of rotation can be reversed. This capability makes bevel gears suitable for applications where changes in direction are required. In contrast, other gears, such as spur gears and helical gears, transmit motion in a specific direction along parallel or skewed axes.

5. Load Distribution: Bevel gears distribute loads differently compared to other gears. Due to the conical shape of the gears, the contact area between the teeth changes as the gears rotate. This can result in varying load distribution along the gear teeth. Other gears, such as spur gears and helical gears, have a consistent load distribution along their teeth due to their cylindrical shape.

6. Applications: Bevel gears are commonly used in applications where changes in direction or speed of rotational motion are required, such as automotive differentials, marine propulsion systems, and power transmission systems. Other types of gears, such as spur gears and helical gears, are more commonly used in applications where parallel or skewed shafts are involved and changes in direction are not necessary.

While bevel gears have their unique characteristics, it’s important to note that different types of gears have their own advantages and applications. The selection of the appropriate gear type depends on factors such as the application requirements, operating conditions, space limitations, and load considerations.

In summary, bevel gears differ from other types of gears in terms of tooth geometry, axis orientation, types of variations available, direction of motion, load distribution, and applications. Their ability to accommodate intersecting shafts and change the direction of rotational motion makes them suitable for specific applications where other types of gears may not be as effective.

editor by Dream 2024-05-06

China wholesaler Superior Precision Helical Gear for New Energy Automobile with ISO9001 supplier

Product Description

Product Parameters

| product name | Superior Precision Helical Gear for New Energy Automobile With ISO9001 |

| stainless steel , iron , aluminum ,bronze ,carbon steel ,brass , nylon etc . | |

| size | ISO standard ,customer requirements |

| BORE | Finished bore, Pilot Bore, Special request |

| surface treatment | Carburizing and Quenching,Tempering ,Tooth suface high quenching Hardening,Tempering |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding…… |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001 |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping ,gear accuracy testing |

| Applications | Toy, Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment,daily living equipment, electronic sports equipment, , sanitation machinery, market/ hotel equipment supplies, etc. |

| Testing Equipment | Rockwell hardness tester 500RA, Double mesh instrument HD-200B & 3102,Gear measurement center instrument CNC3906T and other High precision detection equipments |

Company Profile

Application Field

FAQ

1. why should you buy products from us not from other suppliers?

We are a 32 year-experience manufacturer on making the gear, specializing in manufacturing varieties of gears, such as helical gear ,bevel gear ,spur gear and grinding gear, gear shaft, timing pulley, rack, , timing pulley and other transmission parts .

2. what services can we provide?

Accepted Delivery Terms: Fedex,DHL,UPS;

Accepted Payment Currency:USD,EUR,HKD,GBP,CNY;

Accepted Payment Type: T/T,L/C,PayPal,Western Union;

Language Spoken:English,Chinese

3. how can we guarantee quality?

1 .Always a pre-production sample before mass production;

2 .Always final Inspection before shipment;

3 .We have high-precision CNC gear grinding machine, high-speed CNC gear hobbing machine, CNC gear shaping machine, CNC lathe, CNC machining center, various grinding machines, universal gear measuring instrument, heat treatment and other advanced processing equipment.

4 . We have a group of experienced technical workers, more than 90% of the workers have more than 10 years of work experience in this factory, can accurately control the manufacturing of products and customer needs. We regularly train our employees to ensure that we can produce high-precision and high-quality products that are more in line with our customers’ needs.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

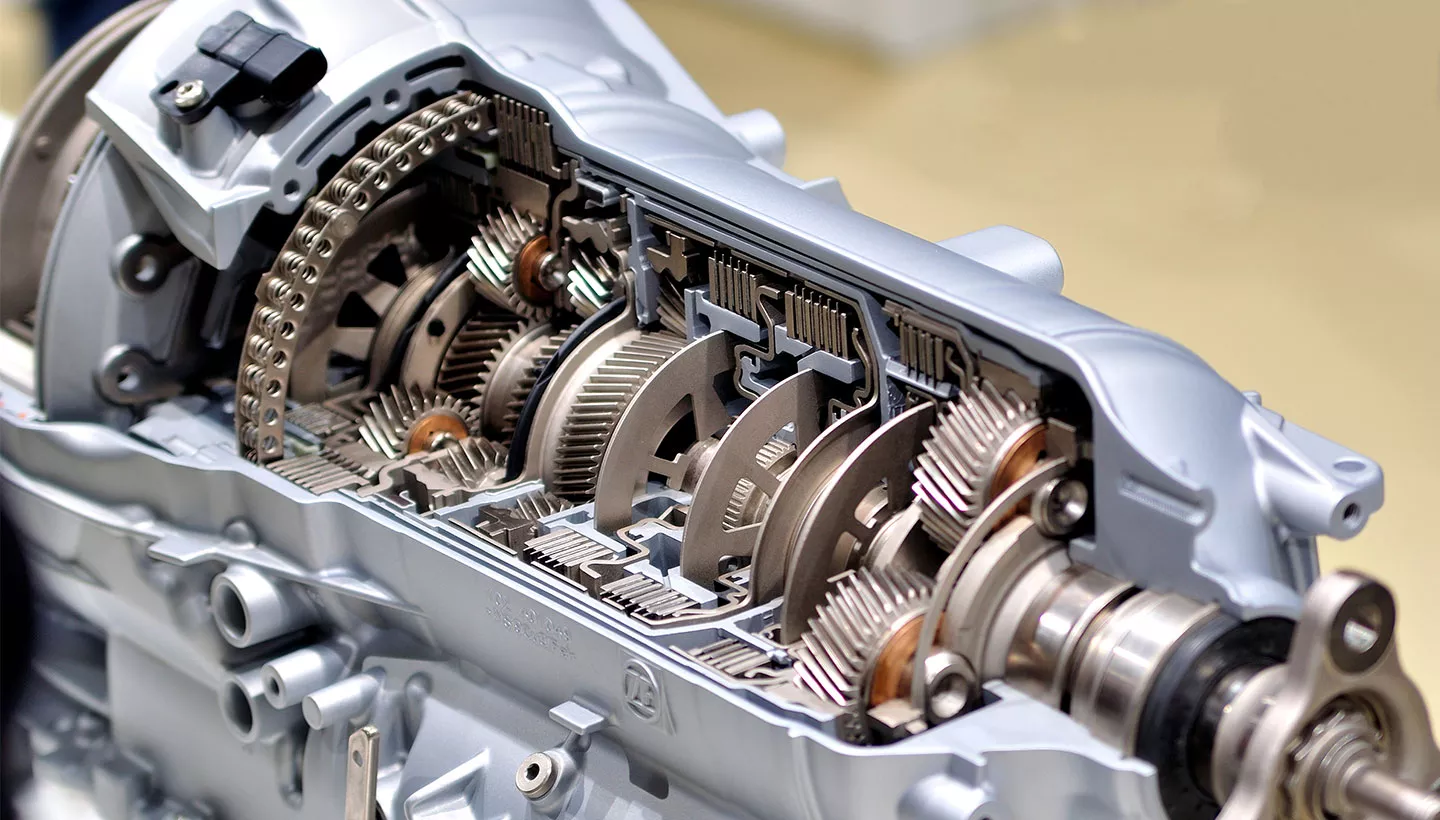

What is the role of the transmission control module (TCM) in a car?

The transmission control module (TCM) plays a crucial role in the operation of the transmission system in a car. Here’s a detailed explanation:

1. Transmission Control:

The primary function of the TCM is to control the operation of the transmission. It receives input from various sensors throughout the vehicle, such as speed sensors, throttle position sensors, engine load sensors, and more. Based on this input, the TCM makes decisions regarding gear selection, shifting points, and torque converter lock-up to ensure optimal performance and efficiency.

2. Shifting Strategy:

The TCM determines the shifting strategy based on the driving conditions and driver inputs. It uses complex algorithms and programming to calculate the ideal timing and characteristics of gear shifts. The shifting strategy can vary depending on factors such as vehicle speed, engine load, throttle position, and driver demand. The TCM’s goal is to provide smooth, seamless, and efficient gear shifts.

3. Fault Detection and Diagnostic Capability:

The TCM continuously monitors the transmission system for any malfunctions or abnormalities. It has built-in diagnostic capabilities to detect faults such as sensor failures, solenoid issues, or hydraulic problems. When a fault is detected, the TCM can often store relevant fault codes, which can be retrieved using specialized diagnostic tools to aid in troubleshooting and repair.

4. Communication with Other Vehicle Systems:

The TCM communicates with other electronic control units (ECUs) in the vehicle to exchange information and coordinate the overall vehicle operation. For example, it may communicate with the engine control module (ECM) to ensure smooth power delivery during gear shifts. It may also communicate with the anti-lock braking system (ABS) to optimize gear selection based on braking conditions.

5. Adaptation and Learning:

Modern TCMs have the capability to adapt and learn over time. They can adjust the shifting strategy based on the driver’s behavior and driving patterns. The TCM may learn the driver’s preferences and adapt the shift points and characteristics accordingly. This adaptive feature helps to tailor the transmission’s behavior to the individual driver’s style and improve overall driving experience.

6. Over-the-Air Updates:

Some TCMs in modern vehicles can receive over-the-air updates. Manufacturers can send software updates to the TCM to refine the shifting algorithms, address known issues, or introduce new features. This capability allows for continuous improvement and optimization of the transmission system even after the vehicle has been sold.

In summary, the transmission control module (TCM) is responsible for controlling and optimizing the operation of the transmission system in a car. It ensures smooth gear shifts, monitors the system for faults, communicates with other vehicle systems, adapts to the driver’s behavior, and can receive software updates for ongoing refinement and improvement.

How does a dual-clutch transmission (DCT) enhance the driving experience?

A dual-clutch transmission (DCT) enhances the driving experience in several ways. Here’s a detailed explanation:

1. Quick and Smooth Gear Shifts:

A DCT utilizes two separate clutches, one for odd-numbered gears and another for even-numbered gears. This dual-clutch setup allows for quick and seamless gear shifts without interrupting power delivery. While one clutch is engaged with the current gear, the other clutch pre-selects the next gear, resulting in near-instantaneous shifts. This quick and smooth shifting enhances acceleration and provides a more engaging driving experience.

2. Continuous Power Delivery:

Since a DCT can shift gears without the need for a torque converter (as in automatic transmissions), there is minimal power loss during gear changes. The power transfer from the engine to the wheels remains uninterrupted, resulting in improved performance and responsiveness. This continuous power delivery contributes to a more dynamic driving experience.

3. Enhanced Fuel Efficiency:

DCTs are designed to optimize fuel efficiency by reducing power losses and maximizing engine performance. The precise and efficient gear changes of a DCT help keep the engine operating in its optimal power band, resulting in improved fuel economy compared to traditional automatic transmissions.

4. Manual Control and Sporty Driving:

Many DCT-equipped vehicles offer manual control modes, such as paddle shifters or a manual shift gate. These modes allow the driver to manually select gears, providing a more involved and sporty driving experience. The ability to control gear changes enhances driver engagement and allows for greater control over the vehicle’s performance.

5. Versatility and Adaptability:

DCTs can adapt to different driving conditions and driver preferences. They often feature multiple driving modes, such as “Normal,” “Sport,” or “Eco,” which adjust shift points, throttle response, and other parameters to suit various driving styles. This versatility allows drivers to tailor the transmission’s behavior to their preferences, whether they prioritize performance, fuel efficiency, or comfort.

6. Suitable for Performance Vehicles:

DCTs are commonly used in high-performance and sporty vehicles due to their ability to provide lightning-fast gear changes and precise control. The rapid and seamless shifts of a DCT contribute to improved acceleration, faster lap times, and enhanced overall performance.

In summary, a dual-clutch transmission (DCT) enhances the driving experience through quick and smooth gear shifts, continuous power delivery, improved fuel efficiency, manual control options, adaptability to different driving conditions, and suitability for performance-oriented vehicles. These features contribute to a more engaging, responsive, and enjoyable driving experience for enthusiasts and drivers seeking a balance between performance and everyday usability.

What are the main functions of the gearbox in a car?

The gearbox, also known as the transmission, performs several important functions in a car. Here’s a detailed explanation:

1. Gear Ratio Selection: One of the primary functions of the gearbox is to provide different gear ratios between the engine and the wheels. By selecting the appropriate gear ratio, the gearbox allows the engine to operate efficiently across a range of speeds and load conditions. Lower gears provide higher torque for starting and climbing hills, while higher gears allow for higher speeds and improved fuel efficiency.

2. Power Transmission: The gearbox is responsible for transmitting power from the engine to the wheels. It takes the rotational power generated by the engine and delivers it to the wheels in a controlled manner. The gearbox ensures that the power is transferred smoothly and efficiently, allowing the vehicle to accelerate, maintain speed, and overcome resistance.

3. Gear Engagement and Disengagement: The gearbox enables the driver to engage or disengage different gears to change the gear ratio. This is typically done using a gearshift mechanism, such as a manual gearshift lever or paddle shifters in automatic transmissions. Gear engagement and disengagement allow the driver to adapt to varying driving conditions, such as starting from a standstill, overtaking, or driving uphill.

4. Gear Synchronization: In manual transmissions, the gearbox incorporates a mechanism called a synchromesh system. This system synchronizes the rotational speeds of the gears before engagement, allowing for smooth gear shifts. It prevents grinding and damage to the gears by equalizing their speeds, ensuring a seamless transition between gears.

5. Reverse Gear: The gearbox provides a reverse gear, allowing the driver to maneuver the vehicle in the opposite direction. The reverse gear has a specific gear ratio that enables the vehicle to move backward safely. It is essential for parking, reversing out of parking spaces, and navigating tight spaces.

6. Neutral Position: The gearbox includes a neutral position that disengages the engine from the wheels. When in neutral, the gearbox allows the engine to run independently without transmitting power to the wheels. This is useful when the vehicle is stationary or when the engine needs to be started or idled without vehicle movement.

7. Mechanical Advantage: The gearbox provides a mechanical advantage by utilizing different gear ratios. It allows the engine to operate within its optimal power band while providing the necessary torque and speed output for various driving conditions. The mechanical advantage offered by the gearbox improves the overall performance and efficiency of the vehicle.

8. Safety Features: Modern gearboxes often incorporate safety features such as a park position (P) or a parking pawl. When engaged, the park position locks the transmission output shaft, preventing the vehicle from rolling unintentionally when parked. This adds an extra layer of safety when the vehicle is stationary.

Overall, the gearbox plays a crucial role in controlling the power, speed, and torque delivery from the engine to the wheels. It allows the driver to adapt to different road conditions, optimize engine performance, and ensure smooth and efficient operation of the vehicle.

editor by Dream 2024-05-06

China manufacturer GB High Quality Steel Spur Gear Customized Large Spur Gears Forged Large Diameter Ring Gear worm and wheel gear

Product Description

Key attributes

Other attributes

Applicable Industries

Manufacturing Plant, Machinery Repair Shops, Construction works

Weight (KG)

2000

Showroom Location

None

Video outgoing-inspection

Not Available

Machinery Test Report

Provided

Marketing Type

Ordinary Product

Warranty of core components

1 Year

Core Components

Gear

Place of CHINAMFG

ZheJiang , China

Condition

New

Warranty

1.5 years

Shape

Ring Gear

Standard or Nonstandard

Nonstandard

Tooth Profile

spur gear/helical gear/customized

Material

Steel

Processing

casting,Forging,hobbing

Pressure Angle

20/40/50/60 Customized

Brand Name

TS

Material

steel, stainless steel customized

Precision

standard precision grade per request

Technique

casting/forging/ customized

Heat Treatment

avaliable

Tooth Profile

Internal Spur/external spur/etc

Features

Professional Production

Application

Industry Machinery

Applicable Standard

ISO/DIN

Gear precision

ordinary/ 8e/7e/6e

Service

Customized OEM

Packaging and delivery

Packaging Details

TS Packaging Details:

1. Bearing surface is covered with the anti-rust oil first; And then wrapped with the plastic film;

2. And then packed with Kraft paper and professional belts;

3. At last, with wooden box totally at the outer packing to in void the rust or the moist;

4. Packaging can be done according to customer’s requirements.

Port

China any Port

Supply Ability

Supply Ability

1500 Set/Sets per Month

Show less

Lead time

| Quantity (sets) | 1 – 1 | > 1 |

| Lead time (days) | 30 | To be negotiated |

OUR WORKSHOPS

OUR EQUIPMENTS

Technology Process

|

Material |

Carbon steel,Alloy steel |

||

|

Structure |

Forging,casting |

||

|

Type of gear |

spur gear,helical gear,Planetary Gear |

||

|

Heat treatment |

Quenching and tempering |

||

|

Process |

forging, rough machining, QT, finish machining |

||

|

Main equipments |

hobbing,CNC machine |

||

|

Module |

up to 200 |

||

|

Precision of gear |

Grinding ISO Grade 5-7 & Hobbing ISO Grade 8-9 |

||

|

Inspection |

Raw material inspection, UT,physical property test,dimension inspect |

||

|

Application |

Mining machinery, mill, kiln and other equipment |

||

OUR CERTIFICATE

OUR CUSTOMER FEEDBACK

CONTACT

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industry |

|---|---|

| Hardness: | Hb190-Hb300 |

| Gear Position: | External Gear |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What is the purpose of using ring gears in machinery?

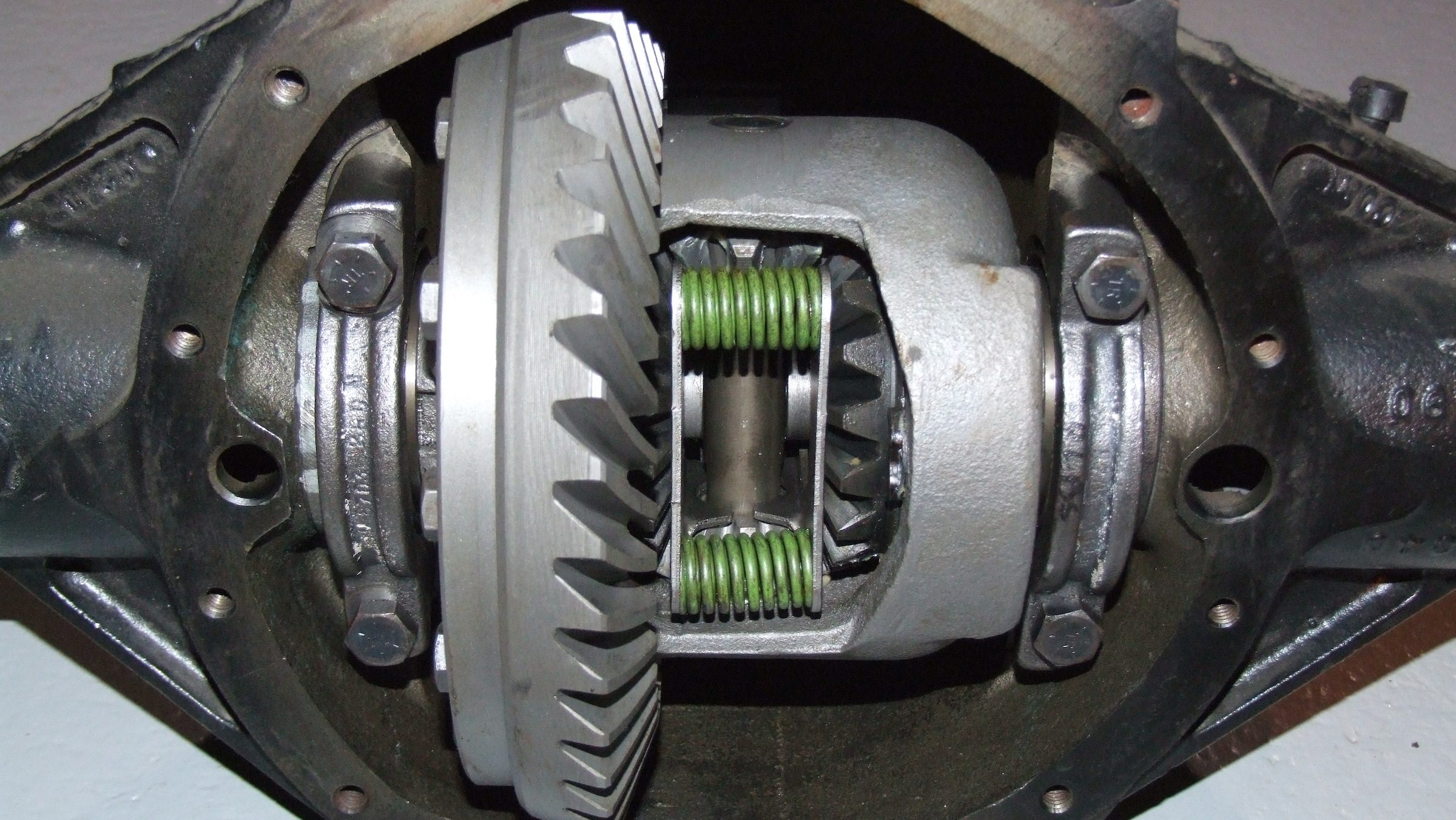

Ring gears serve multiple purposes and offer various advantages when used in machinery. Here’s a detailed explanation of the purpose of using ring gears:

- Power Transmission: One of the primary purposes of ring gears in machinery is to facilitate power transmission. Ring gears, along with other meshing gears, transmit torque and rotational motion from the driving gear to the driven components or systems. They enable the transfer of power from a power source to various parts of the machinery, driving the movement and operation of different mechanisms and processes.

- Gear Ratio Control: Ring gears allow for precise control over the gear ratio in machinery. By adjusting the size of the ring gear and its meshing gears, different gear ratios can be achieved. Gear ratios determine the relationship between the rotational speeds and torques of the driving and driven gears. This ability to control the gear ratio enables machinery to operate at desired speeds, optimize torque output, and adapt to specific application requirements.

- Mechanical Advantage: Ring gears provide a mechanical advantage in machinery. By leveraging the gear ratio control mentioned above, ring gears can amplify or reduce the torque output of the power source. This mechanical advantage allows machinery to generate higher forces or torques than the original power source alone. It enables the machinery to handle heavy loads, perform tasks requiring significant force, and enhance overall operational efficiency.

- Load Distribution: Ring gears contribute to load distribution within machinery. The meshing teeth of the ring gear engage with multiple teeth of other gears, distributing the transmitted loads across these meshing points. This load distribution helps prevent excessive stress concentration on specific gear teeth, ensuring even wear and reducing the risk of gear failure. By distributing the load, ring gears enhance the overall durability and reliability of the machinery.

- Motion Control: Ring gears play a crucial role in motion control within machinery. By transmitting rotational motion, ring gears enable precise movement and synchronization of various components and mechanisms. They ensure that different parts of the machinery operate in a coordinated manner, allowing for smooth and controlled motion. Ring gears contribute to accurate positioning, speed regulation, and overall motion precision in machinery.

- Compact Design: Ring gears offer a compact design solution. Due to their annular shape, they can be integrated into machinery with limited space. The compactness of ring gears is particularly beneficial in applications where space constraints are a concern. Their small footprint allows for efficient use of available space, enabling the design of more compact and lightweight machinery without sacrificing power transmission capabilities.

- Versatile Applications: Ring gears find wide applications across various industries and machinery types. They are used in automotive transmissions, industrial machinery, robotics, aerospace systems, power generation equipment, and more. The versatility of ring gears stems from the ability to configure them in different types, such as external or internal ring gears, helical gears, or bevel gears. This versatility makes ring gears adaptable to a wide range of machinery designs and requirements.

By serving these purposes, ring gears contribute to the efficient and reliable operation of machinery. They enable power transmission, gear ratio control, mechanical advantage, load distribution, motion control, and compact design, making them essential components in various mechanical systems.

Are ring gears suitable for high-torque applications?

Ring gears are indeed suitable for high-torque applications. Here’s a detailed explanation of why ring gears are suitable for high-torque applications:

Ring gears are designed to handle high torque loads and are commonly used in various applications that require substantial torque transmission. Here are the reasons why ring gears are well-suited for high-torque applications:

- Robust Construction: Ring gears are typically constructed with robust materials, such as hardened steel or other high-strength alloys. This construction provides the necessary strength, durability, and resistance to withstand high torque forces without deformation or failure.

- Large Contact Area: Ring gears have a large contact area between their gear teeth, which allows for efficient power transmission and load distribution. The larger contact area enables the ring gear to transmit higher torque without experiencing excessive stress concentrations or localized overloading.

- Optimized Tooth Geometry: The tooth geometry of ring gears is designed to handle high torque. The shape and profile of the gear teeth are optimized to distribute the torque load evenly, minimizing stress concentrations and enhancing the gear’s ability to transmit higher torque without premature wear or failure.

- Multiple Gear Engagements: Ring gears often engage with multiple gears or pinions, which further enhances their torque capacity. The engagement of multiple gears allows for load sharing, distributing the torque across multiple contact points and reducing the strain on individual gear teeth.

- Customizable Gear Ratios: Ring gears can be designed with various gear ratios to meet specific torque requirements. By adjusting the tooth count or diameter of the ring gear and mating gears, the gear system can be optimized for high torque applications while maintaining the desired speed or rotational characteristics.

- Used in Heavy-Duty Applications: Ring gears are widely used in heavy-duty applications that demand high torque transmission. Examples include automotive differentials, industrial gearboxes, mining equipment, construction machinery, and wind turbines. These applications rely on ring gears to effectively transmit and handle the high torque generated by powerful engines, motors, or turbines.

It’s important to note that while ring gears are suitable for high-torque applications, proper engineering analysis and selection should be carried out to ensure that the specific design, material, and size of the ring gear are appropriate for the intended torque requirements. Factors such as gear tooth strength, gear geometry, material properties, lubrication, and operating conditions should be carefully considered to ensure reliable and efficient performance in high-torque applications.

What industries commonly use ring gears?

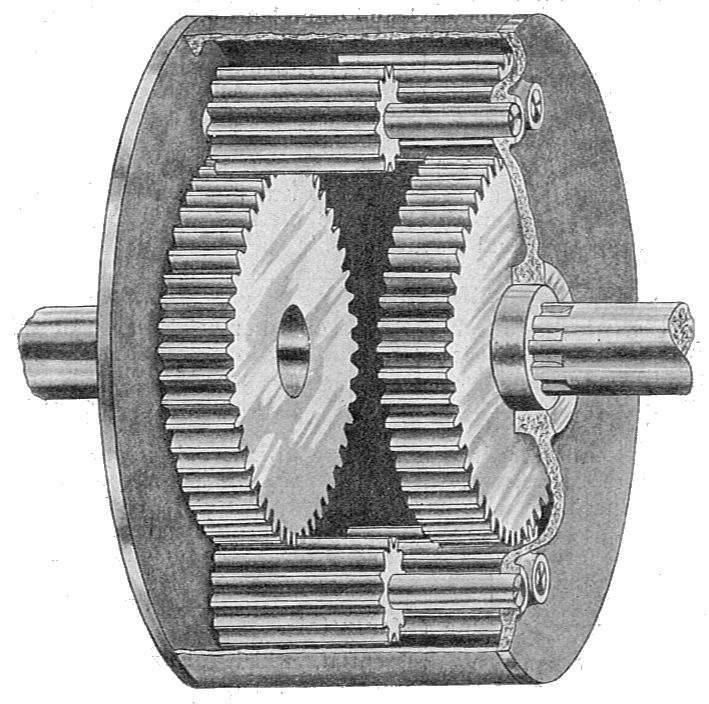

Ring gears, also known as annular gears or internal gears, are utilized in various industries due to their unique characteristics and capabilities. Here’s a detailed explanation of the industries that commonly use ring gears:

- Automotive Industry: Ring gears are extensively used in the automotive industry. They are a crucial component in automotive transmissions, differential systems, and steering mechanisms. Ring gears help transmit torque and rotational motion, enabling smooth shifting of gears and efficient power transfer in vehicles.

- Aerospace Industry: The aerospace industry relies on ring gears for various applications. They are used in aircraft engines, landing gear systems, actuation mechanisms, and aerospace gearboxes. Ring gears provide reliable and precise motion control in critical aerospace systems.

- Industrial Machinery: Ring gears find wide applications in industrial machinery, including heavy machinery, manufacturing equipment, and power generation systems. They are used in gearboxes, speed reducers, and other power transmission systems. Ring gears enable efficient torque transfer and motion control in industrial settings.

- Robotics: Ring gears play a significant role in robotics and automation. They are employed in robotic joints, manipulator arms, and motion control systems. Ring gears provide precise and smooth rotation, allowing robots to perform intricate tasks with accuracy and repeatability.

- Power Generation: Ring gears are utilized in power generation equipment such as wind turbines, hydroelectric generators, and steam turbines. They are part of the gearbox systems that convert the rotational motion of the turbine blades into electrical energy. Ring gears enable efficient power transmission and adaptability to varying load conditions.

- Heavy Equipment and Construction: The heavy equipment and construction industry extensively use ring gears in equipment like excavators, cranes, loaders, and bulldozers. They are vital for the operation of the drivetrain and hydraulic systems, enabling controlled movement and power transfer in demanding construction environments.

- Marine Industry: Ring gears are employed in various marine applications, including ship propulsion systems, marine winches, and steering mechanisms. They provide reliable torque transfer and motion control in marine vessels, ensuring efficient navigation and maneuverability.

- Renewable Energy: Ring gears are utilized in renewable energy systems such as solar tracking systems and tidal power generation. They enable the precise tracking of solar panels and the efficient conversion of tidal forces into electrical energy.

The diverse applications of ring gears across these industries highlight their versatility and importance in various mechanical systems. The specific design, size, and material selection of ring gears may vary depending on the industry requirements and operating conditions.

editor by Dream 2024-05-06

China Good quality Pinion Spur Large CZPT Custom Forging Ball Mill Gear Helical Wheel Gear Made in China gear patrol

Product Description

Pinion Spur Large CHINAMFG Custom Forging Ball Mill Gear Helical Wheel Gear Made In China

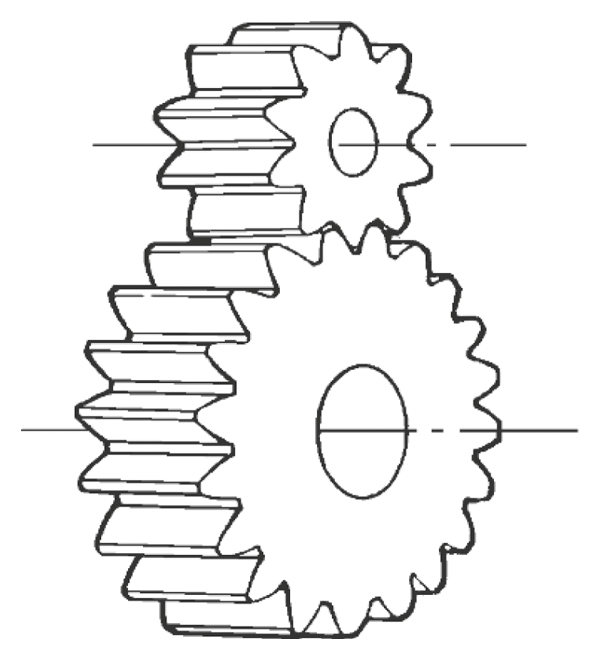

There are many types of gears such as spur gears, helical gears, bevel gears, worm gears, gear rack, etc. These can be broadly classified by looking at the positions of axes such as parallel shafts, intersecting shafts and non-intersecting shafts.

It is necessary to accurately understand the differences among gear types to accomplish necessary force transmission in mechanical designs. Even after choosing the general type, it is important to consider factors such as: dimensions (module, number of teeth, helix angle, face width, etc.), standard of precision grade (ISO, AGMA, DIN), need for teeth grinding and/or heat treating, allowable torque and efficiency, etc.

Spur Gear

Gears having cylindrical pitch surfaces are called cylindrical gears. Spur gears belong to the parallel shaft gear group and are cylindrical gears with a tooth line which is straight and parallel to the shaft. Spur gears are the most widely used gears that can achieve high accuracy with relatively easy production processes. They have the characteristic of having no load in the axial direction (thrust load). The larger of the meshing pair is called the gear and smaller is called the pinion.

Helical Gear

Helical gears are used with parallel shafts similar to spur gears and are cylindrical gears with winding tooth lines. They have better teeth meshing than spur gears and have superior quietness and can transmit higher loads, making them suitable for high speed applications. When using helical gears, they create thrust force in the axial direction, necessitating the use of thrust bearings. Helical gears come with right hand and left hand twist requiring opposite hand gears for a meshing pair.

Gear Rack

Same sized and shaped teeth cut at equal distances along a flat surface or a straight rod is called a gear rack. A gear rack is a cylindrical gear with the radius of the pitch cylinder being infinite. By meshing with a cylindrical gear pinion, it converts rotational motion into linear motion. Gear racks can be broadly divided into straight tooth racks and helical tooth racks, but both have straight tooth lines. By machining the ends of gear racks, it is possible to connect gear racks end to end.

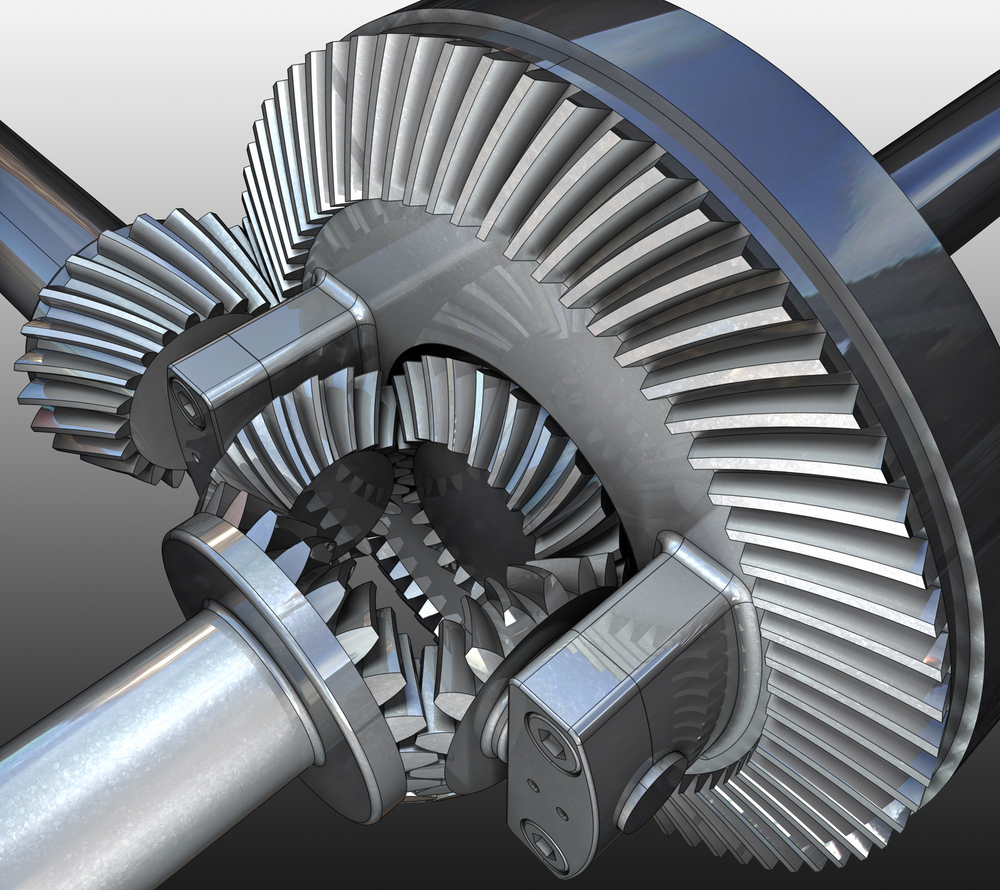

Bevel Gear

Bevel gears have a cone shaped appearance and are used to transmit force between 2 shafts which intersect at 1 point (intersecting shafts). A bevel gear has a cone as its pitch surface and its teeth are cut along the cone. Kinds of bevel gears include straight bevel gears, helical bevel gears, spiral bevel gears, miter gears, angular bevel gears, CHINAMFG gears, zerol bevel gears and hypoid gears.

Screw Gear

Screw gears are a pair of same hand helical gears with the twist angle of 45° on non-parallel, non-intersecting shafts. Because the tooth contact is a point, their load carrying capacity is low and they are not suitable for large power transmission. Since power is transmitted by the sliding of the tooth surfaces, it is necessary to pay attention to lubrication when using screw gears.

Worm Gear

A screw shape cut on a shaft is the worm, the mating gear is the worm wheel, and together on non-intersecting shafts is called a worm gear. Worms and worm wheels are not limited to cylindrical shapes. There is the hour-glass type which can increase the contact ratio, but production becomes more difficult. Due to the sliding contact of the gear surfaces, it is necessary to reduce friction. For this reason, generally a hard material is used for the worm, and a soft material is used for worm wheel. Even though the efficiency is low due to the sliding contact, the rotation is smooth and quiet. When the lead angle of the worm is small, it creates a self-locking feature.

Internal gear

Internal gears have teeth cut on the inside of cylinders or cones and are paired with external gears. The main use of internal gears are for planetary gear drives and gear type shaft couplings. There are limitations in the number of teeth differences between internal and external gears due to involute interference, trochoid interference and trimming problems. The rotational directions of the internal and external gears in mesh are the same while they are opposite when 2 external gears are in mesh.

|

Product name |

Spur Gear & Helical Gear & Gear Shaft |

|

Materials Available |

Stainless Steel, Carbon Steel, Brass, Bronze, Iron, Aluminum Alloy etc |

|

Heat Treatment |

Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding…… |

|

Surface Treatment |

Carburizing and Quenching,Tempering ,Tooth suface high quenching Hardening,Tempering |

|

BORE |

Finished bore, Pilot Bore, Special request |

|

Processing Method |

Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc |

|

Pressure Angle |

20 Degree |

|

Hardness |

55- 60HRC |

|

Size |

Customer Drawings & ISO standard |

|

Package |

Wooden Case/Container and pallet, or made-to-order |

|

Certificate |

ISO9001:2008 |

|

Machining Process |

Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

|

Applications |

Toy, Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment,daily living equipment, |

|

Advantages |

1. Produce strictly in accordance with ANSI or DIN standard dimension |

Product Process

Application:

About Us:

HangZhou MC Bearing Technology Co.,Ltd (LYMC),who is manufacture located in bearing zone, focus on Slewing bearing, cross roller bearing and pinion,Dia from 50mm-8000mm, Our team with technical and full experience in the bearing industry.

*Professional in researching, developing, producing & marketing high precision bearings for 16 years;

*Many series bearings are on stock; Factory directly provide, most competitive price;

*Advanced CNC equipment, guarantee product accuracy & stability;

*One stop purchasing, product include cross roller bearing, rotary table bearing, robotic bearing, slewing bearing, angular contact ball bearing, large and extra large custom made bearing, diameter from 50~9000mm;

*Excellent pre-sale & after sale service. We can go to customers’ project site if needed.

*Professional technical & exporting team ensure excellent product design, quotation, delivering, documentation & custom clearance.

Our Service:

FAQ:

1.Q: Are you trading company or manufacturer ?

A: We are professional slewing bearing manufacturer with 20 years’ experience.

2.Q: How long is your delivery time?

A: Generally it is 4-5 days if the goods are in stock. or it is 45 days if the goods are not in

stock, Also it is according to quantity.

3.Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample, it is extra.

4.Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance, balance before shipment.

5.Q: Can you provide special customization according to the working conditions?

A: Sure, we can design and produce the slewing bearings for different working conditions.

6.Q: How about your guarantee?

A: We provide lifelong after-sales technical service.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Marine, Agricultural Machinery, Mining, Petroleum, Automatic,Excavator,Crane, |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Toothed Portion Shape: | Helical Bevel Gear |

| Material: | Stainless Steel |

| Type: | Non-Circular Gear |

| Customization: |

Available

| Customized Request |

|---|

Can spur gears be used in precision manufacturing equipment?

Yes, spur gears can be used in precision manufacturing equipment. Here’s a detailed explanation:

Precision manufacturing equipment requires high accuracy, repeatability, and reliability to produce intricate and precise components. While other gear types like helical gears or bevel gears are commonly used in precision applications, spur gears can also be suitable in certain scenarios.

1. Low-Speed Applications:

Spur gears are well-suited for low-speed applications where high precision is required. In precision manufacturing equipment, such as milling machines, lathes, or grinding machines, where controlled and precise rotational motion is essential, spur gears can provide the necessary power transmission with accuracy.

2. Linear Actuators and Positioning Systems:

Spur gears can be used in linear actuators and positioning systems within precision manufacturing equipment. These systems require precise movement control, and spur gears can convert rotary motion into linear motion accurately. By incorporating precision-ground spur gears with proper backlash control, highly accurate positioning can be achieved.

3. Tooling Systems:

Spur gears are employed in tooling systems used in precision manufacturing equipment, such as indexing heads and rotary tables. These systems enable precise and repeatable positioning of workpieces or cutting tools. Spur gears with high precision tooth profiles and low backlash are utilized to ensure accurate tool positioning and consistent machining results.

4. Measuring and Inspection Equipment:

In precision manufacturing, gear systems are also utilized in measuring and inspection equipment. Spur gears can be incorporated into gear trains within instruments like coordinate measuring machines (CMMs) or optical comparators to translate linear or rotary motion into precise measurement data. The gear systems in these instruments require minimal backlash and high accuracy to ensure accurate measurements.

5. Customized Gear Systems:

In some cases, precision manufacturing equipment may require custom-designed gear systems to meet specific application requirements. Spur gears can be tailored and optimized for these custom gear systems, taking into account factors like gear tooth profile, material selection, and gear geometry. This allows for the creation of highly precise and specialized gear systems.

While spur gears have advantages in precision manufacturing equipment, it’s important to consider their limitations. Due to their design, spur gears may produce more noise and vibration compared to other gear types. Additionally, they are generally not suitable for high-speed or high-torque applications that demand continuous and smooth power transmission.