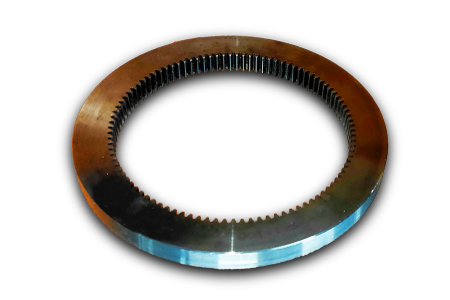

Product Description

Our advantage:

*Specialization in CNC formulations of high precision and quality

*Independent quality control department

*Control plan and process flow sheet for each batch

*Quality control in all whole production

*Meeting demands even for very small quantities or single units

*Short delivery times

*Online orders and production progress monitoring

*Excellent price-quality ratio

*Absolute confidentiality

*Various materials (stainless steel, iron, brass, aluminum, titanium, special steels, industrial plastics)

*Manufacturing of complex components of 1 – 1000mm.

Production machine:

| Specification | Material | Hardness |

| Z13 | Steel | HRC35-40 |

| Z16 | Steel | HRC35-40 |

| Z18 | Steel | HRC35-40 |

| Z20 | Steel | HRC35-40 |

| Z26 | Steel | HRC35-40 |

| Z28 | Steel | HRC35-40 |

| Custom dimensions according to drawings | Steel | HRC35-40 |

Production machine:

Inspection equipment :

Gear tester

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Steel |

| Customization: |

Available

| Customized Request |

|---|

What lubrication is required for ring gears?

Proper lubrication is essential for the optimal performance and longevity of ring gears. Here’s a detailed explanation of the lubrication requirements for ring gears:

- Type of Lubricant: The type of lubricant used for ring gears depends on various factors, including the application, operating conditions, and gear design. Common lubricants for ring gears include gear oils, grease, and synthetic lubricants. Gear oils are specifically formulated for gear systems and provide excellent lubrication and protection against wear. Grease is often used in applications where the gear system operates at lower speeds or requires higher viscosity lubrication. Synthetic lubricants offer enhanced performance, durability, and resistance to extreme temperatures and loads.

- Lubricant Properties: The lubricant chosen for ring gears should possess certain properties to ensure effective lubrication. These properties include high film strength, good thermal stability, resistance to oxidation, and anti-wear characteristics. The lubricant should also be compatible with the materials used in the ring gear system to prevent damage or degradation of the gear surfaces.

- Viscosity: Viscosity is an important consideration when selecting lubrication for ring gears. Viscosity refers to the thickness or resistance to flow of the lubricant. It is crucial to choose a lubricant with the appropriate viscosity to ensure proper lubrication film formation between the gear teeth. If the lubricant’s viscosity is too low, it may not provide sufficient lubrication, leading to increased wear. Conversely, if the viscosity is too high, it may cause excessive friction and energy loss. The recommended viscosity range is typically specified by the gear manufacturer or industry standards.

- Lubrication Method: The lubrication method for ring gears can vary depending on the specific application and gear system design. For enclosed gear systems, such as gearboxes or sealed housings, lubrication is typically performed by filling the housing with the recommended lubricant to the appropriate level. In open gear systems, such as large industrial gears, lubricant application methods may include spray systems, drip lubrication, or circulation systems. The lubrication method should ensure sufficient coverage and distribution of the lubricant to all gear surfaces.

- Lubrication Frequency: Regular lubrication maintenance is crucial to keep ring gears properly lubricated. The frequency of lubrication depends on the operating conditions, gear system design, and the lubricant used. It is important to follow the manufacturer’s recommendations or industry standards regarding lubrication intervals. Regular inspections should also be conducted to monitor the lubricant condition, check for contamination, and replenish or replace the lubricant as needed.

- Environmental Considerations: Environmental factors, such as temperature, moisture, and contamination, can affect the performance of the lubricant and the ring gears. It is important to consider these factors when selecting the lubricant. Extreme temperatures may require lubricants with enhanced thermal stability, while exposure to moisture or harsh contaminants may necessitate lubricants with better resistance to corrosion or water washout.

To ensure the proper lubrication of ring gears, it is advisable to consult the gear manufacturer’s recommendations and guidelines. They can provide specific information regarding the suitable lubricant type, viscosity range, lubrication method, and maintenance practices for the particular ring gear system.

How do you maintain and service a ring gear system?

Maintaining and servicing a ring gear system is crucial to ensure its optimal performance, reliability, and longevity. Here’s a detailed explanation of the maintenance and service procedures for a ring gear system:

- Regular Inspections: Conduct regular inspections of the ring gear system to detect any signs of wear, damage, misalignment, or abnormal conditions. Inspect the gear teeth for chips, cracks, or excessive wear. Check for proper gear engagement and backlash. Inspect the mounting bolts or fasteners for tightness. Regular inspections help identify potential issues early on and prevent further damage or failures.

- Cleaning and Lubrication: Clean the ring gear system periodically to remove dirt, debris, and old lubricant. Use appropriate cleaning methods and solvents that are compatible with the gear system materials. After cleaning, apply fresh lubricant according to the manufacturer’s recommendations. Ensure proper lubrication coverage and distribution to minimize friction, wear, and heat generation.

- Lubricant Analysis: Periodically analyze the condition of the lubricant in the ring gear system to assess its effectiveness and detect any contamination or degradation. Lubricant analysis involves collecting samples and sending them to a laboratory for testing. The analysis results can provide valuable information about the lubricant’s viscosity, contamination levels, and overall condition. Based on the analysis, determine whether lubricant replacement or additional maintenance actions are necessary.

- Bearing and Seal Inspection: If the ring gear system includes bearings or seals, inspect them regularly for wear, damage, or leaks. Check for excessive play, noise, or overheating in the bearings. Inspect the seals for proper sealing and lubricant retention. Replace any worn-out bearings or damaged seals to prevent further damage to the ring gear system.

- Torque Checks: Periodically check the torque of the mounting bolts or fasteners that secure the ring gear system. Over time, vibrations and operational stresses can cause bolts to loosen. Ensure that the bolts are tightened to the manufacturer’s recommended torque specifications. Perform torque checks during scheduled maintenance intervals or when any signs of loosening are observed.

- Alignment and Gear Meshing: Check and adjust the alignment of the ring gear system if necessary. Misalignment can lead to uneven wear, increased load on the gear teeth, and reduced performance. Ensure proper gear meshing and backlash according to the manufacturer’s specifications. Adjust the gear positioning or contact pattern if deemed necessary during inspections or maintenance activities.

- Repair or Replacement: If any significant damage, wear, or malfunction is identified during inspections or maintenance activities, plan for repair or replacement of the affected components. Depending on the severity and nature of the issue, repairs may involve repairing gear teeth, replacing damaged parts, or realigning the gear system. If extensive damage is present or the gear system has reached the end of its service life, consider replacing the entire ring gear system.

- Documentation and Record-Keeping: Maintain detailed documentation and records of all maintenance and service activities performed on the ring gear system. Keep track of inspection results, lubrication schedules, repairs, parts replacements, and any other relevant information. These records help establish a maintenance history, track performance trends, and provide valuable reference information for future maintenance and troubleshooting.

It’s important to note that the specific maintenance and service procedures may vary depending on the type of ring gear system, its application, and the manufacturer’s guidelines. Always refer to the manufacturer’s recommendations and consult with experts or professionals when necessary to ensure proper maintenance and servicing of the ring gear system.

How do ring gears differ from other types of gears?

Ring gears, also known as annular gears or internal gears, possess distinct characteristics that set them apart from other types of gears. Here’s a detailed explanation of how ring gears differ from other gears:

1. Tooth Configuration: The most significant difference between ring gears and other gears is their tooth configuration. In a ring gear, the teeth are located on the inside circumference of a circular ring, whereas in other gears such as spur gears, helical gears, and bevel gears, the teeth are present on the outer surface of the gear. This internal tooth arrangement makes ring gears unique and allows them to mesh with pinion gears or other external gears.

2. Gear Assembly: The assembly of ring gears differs from other gears. In most cases, ring gears are used in combination with pinion gears or other external gears. The pinion gear meshes with the teeth on the inside of the ring gear. This gear set configuration enables the transmission of rotational motion and torque.

3. Load Distribution: Ring gears distribute the load over a larger area compared to other types of gears. The load is spread across the internal teeth of the ring gear, resulting in improved load-carrying capacity and enhanced gear durability. This load distribution characteristic makes ring gears suitable for applications that involve high loads or continuous operation.

4. Gear Ratio: Ring gears offer specific advantages in terms of gear ratios. They are commonly used in applications where high gear ratios are required. The gear ratio is determined by the number of teeth on the ring gear compared to the number of teeth on the mating gear (such as a pinion gear). The internal tooth configuration of the ring gear allows for larger gear diameters, enabling higher gear ratios to be achieved.

5. Space Utilization: Ring gears provide a compact design compared to some other types of gears. The internal tooth arrangement allows for a more space-efficient gear assembly. This compactness is advantageous in applications where space is limited or where a high gear ratio needs to be achieved within a confined area.

6. Applications: Ring gears are commonly used in automotive transmissions, differential systems, planetary gear systems, industrial machinery, robotics, power generation equipment, and heavy machinery. Their unique characteristics make them suitable for applications that require precise motion control, load distribution, and high gear ratios.

It’s important to note that the specific design, tooth profile, material selection, and manufacturing techniques may vary for different types of gears, including ring gears. Each type of gear is designed to meet specific application requirements, operating conditions, and performance needs.

editor by Dream 2024-04-25