Product Description

Product Description

Our Gear types: Straight Teeth Gear, sprocket, Oblique Teeth Cylinder Gear, External Spur Gear, Internal Spur Gear, Gear Shaft etc the standard and non standard according to the drawings or samples.

Material: 45#, 40Cr, 20CrMo, 20CrMoti, 17CrNiMo6, 20CrMnTi or the others

Heat treatment: Medium frequency quenching, high frequency quenching, carburizing and quenching, nitriding, Carbon-Nitriding, Salt bath quenching.

Working Process: Gearh hobbing, Gear shaving, Gear shaping, Gear grinding etc

Precision Grade: GB5-8, JIS 1-4, AGMA 12-9, DIN 6-9

Application area: Auto gearbox, medical equipment, metallurgical machinery, port machinery, lifting equipment, mining machinery, electrical power equipment, light industry equipment, environmental protection machinery.

Detailed Photos

Product Parameters

Take the example of our sprocket or chainwheel

The standard and non standard according to the drawings or samples.

Material: C45, S235JR, CAST STEEL or the others

1, Description: Sprocket, chainwheel

2, Types:

A) Standard sprocket

B) Finished bore sprocket

C) Taper bore sprocket

D) Double plate wheels

E) conveyor sprocket

3, Material: C45, S235JR, Nylon

4, Surface treatment: Zinc-plated, black finish

5, Single A-type, double A-type, Welding hub KB-type, Welding hub C-type etc for your reference.

6. Process: Forging( casting)—lathe- teeth shaping—finishing—oil washing—Packing, made by CNC machine

7. Inspection: All items are checked and tested thoroughly during every working procedure and after the product is finally manufactured to ensure that the best quality product enter into the market.

Packaging & Shipping

Our Advantages

After Sales Service

Our Core range of spur gears, industry sprocket, and roller chains are specifically designed to be interchangeable and versatile, this helps us keep lower stock levels while achieving the customization necessary for so many applications. The core offer has also enabled us to offer excellent pricing levels for low quantities, often prototypes are very expensive due to lack of economies of scale we have tried to help with this as much as possible. HangZhou CHINAMFG can offer bespoke units for larger quantities and offer a Supply Chain service where we work closely with our customers to identify the optimal delivery schedule in accordance with OEM production levels. If you are looking for spur gear, drive shafts, industry sprocket etc, you have come to the right place, our expert technical sales staff will recommend the best possible option for both your application and your pocket. Contact us now to discuss your application.

HangZhou CHINAMFG TRADE CO., LTD is responsible for exporting the above products, and we also import some important products from oversea markets.

Our company has got the right of import and export from the Government department.

It is necessary to get your specific requirement when contacting us,

for example of gear, number of teeth, module, pitch diameter, inner hole diameter, thickness, outside drawing etc. and then we will give the accurate offers.

Therefore, hope to get your feedback soon.

Please watch our process steps as below

(1) process these output shafts

(2)process these spur gears and sprockets

(3) turning machining

(4) assembly preparation

(5) fine process workshop

CHOOSE US FOR:

1. We offer engineer suggestion to your specified design in production improvement and cost saving.

2. R&D and QC department focus on the products to meet your strict requirements.

3. Different surface treatments available, plating, power coating, painting, anodized,polishing, electrophoresis, etc.

4. Different dimensions according to buyer’s request.

5. Various packagings according to specific requirements.

6. Customized and tailored orders are welcome.

7. Good quality and Quick action.

8. Our products have been exported to America, Australia,German,Korea,Indian.

CONFIDENTIAL POLICY:

1) The appointed products are only for you.

2) Your informations&documents are confidential.

3) Your drawings&sketch are confidential.

FAQ

Question:

1.Q:How about mould cost?

A: primarily depend on : 1.Drawing, 2.material, 3.weight and quantity.

We need to know the structure of each parts to analyze the mold solution by:

1) –Complete design drawing or actual sample —– the best way

–PDF drawing with complete dimension for each parts

–Clearly photos for each parts with more angle-views to show every features.

2)The materials and surface treatments.

3)The quantity of order.

2.Q:How to control the product processing?

A: The processing report or pictures will be sent to the customer every week/ each month for review.

3.Q:Who will own the mould?

A:Customer, also the mould can be kept in our factory for future order.

4.Q:How long do you make your quotation?

A:After receiving detail informations we will quote in 1 to 3 days.

5.Q: Are the samples/prototype free of charge?

A: charged,but it will be returned to buyer when an order confirmed and order quantity is over 5000 pcs.

After your drawing confirmed and charges done for the prototype, we will produce a sample

by CNC machining. And the first trial samples (1-3pcs) will be shipped to buyer

by the DHL /Fedex at buyer’s express account or prepay the express charges.

MOQ? — 200units and accept sample order.

| Application: | Motor, Machinery, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Alloy Steel |

| Samples: |

US$ 445.20/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

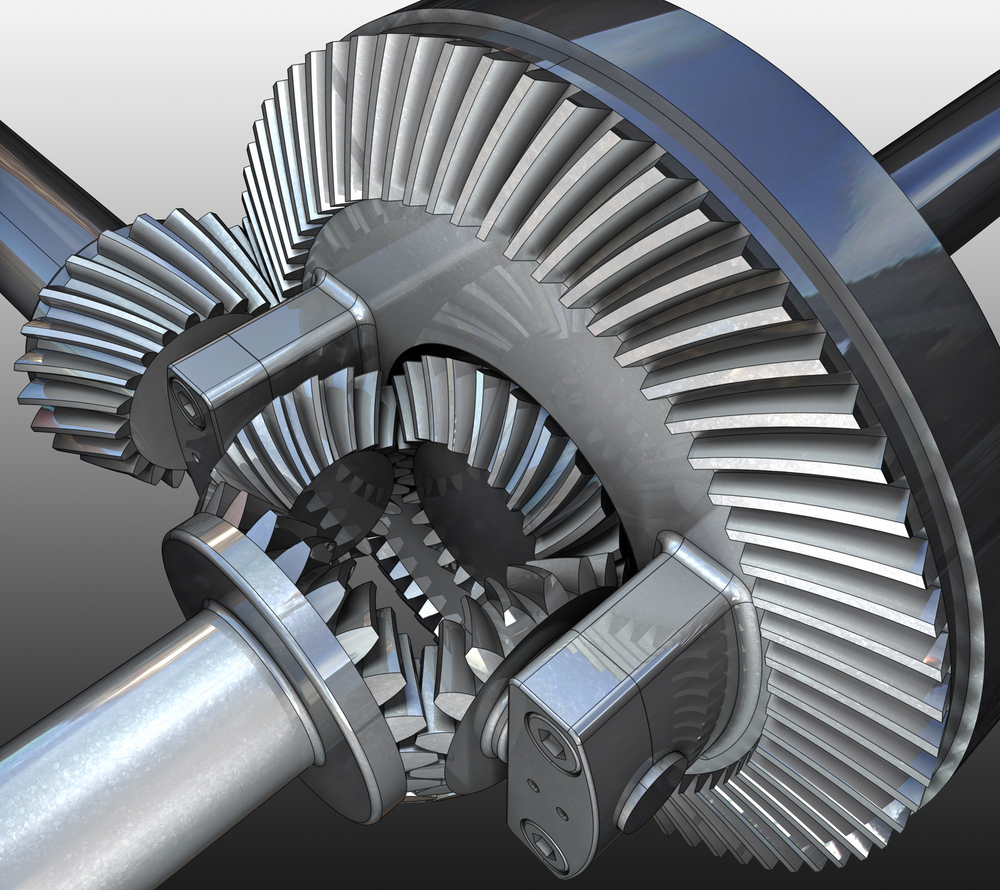

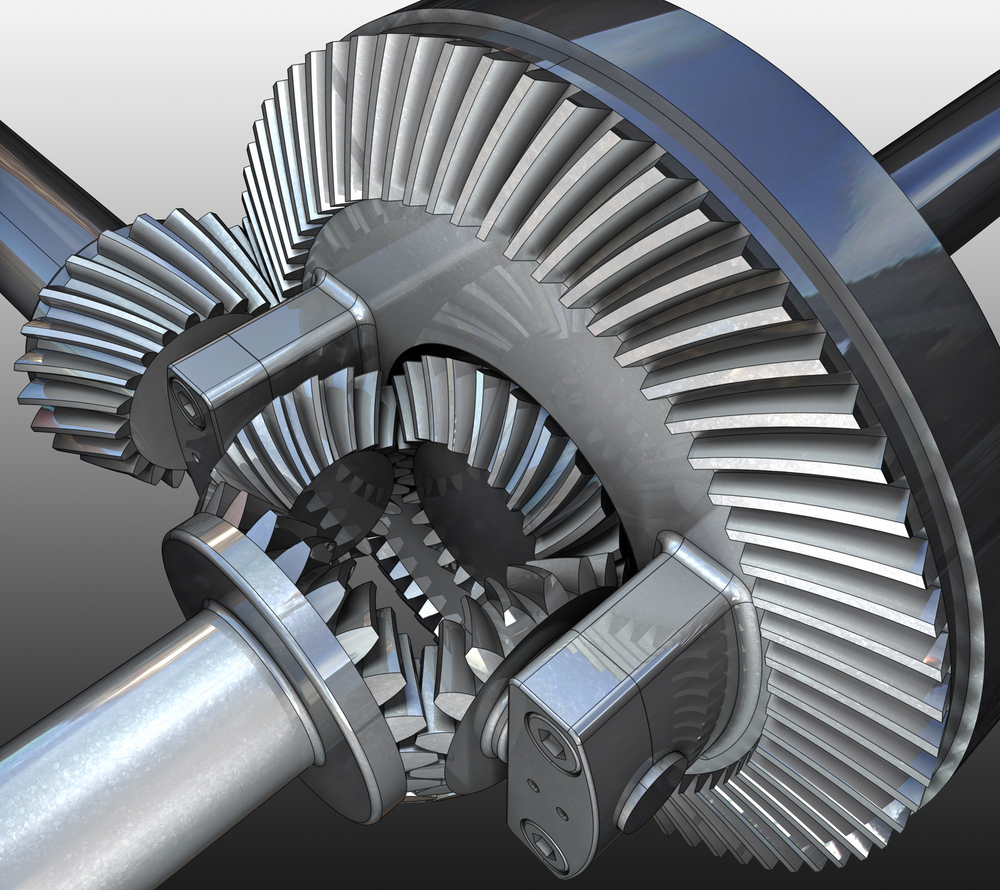

How does a differential gear distribute power between the wheels?

A differential gear is responsible for distributing power between the wheels of a vehicle, allowing them to rotate at different speeds while maintaining torque transfer. Here’s a detailed explanation of how a differential gear accomplishes this:

1. Power Input:

The differential gear receives power from the transmission or driveshaft connected to the engine. This power is transmitted to the differential assembly, which is typically located in the axle housing.

2. Ring and Pinion Gears:

Within the differential assembly, the power from the driveshaft is transferred to the ring and pinion gears. The ring gear is a large gear that surrounds the differential assembly, while the pinion gear is a smaller gear connected to the driveshaft. The interaction between these gears allows the power to be redirected.

3. Side Gears and Spider Gears:

The ring gear is connected to side gears, also known as bevel gears, through a set of small gears called spider gears. The side gears are attached to the axle shafts, which are responsible for transmitting power to the wheels. The spider gears allow the side gears to rotate independently of each other while maintaining torque transfer.

4. Differential Action:

As the vehicle moves, the differential gears enable the wheels to rotate at different speeds during turns. When the vehicle is moving in a straight line, the spider gears rotate smoothly, allowing equal power distribution to both wheels. However, during a turn, the inside wheel travels a shorter distance than the outside wheel, causing them to rotate at different speeds.

5. Speed and Torque Distribution:

The differential gear adjusts the speed and torque distribution between the wheels based on their rotational differences. When the vehicle is turning, the spider gears allow one wheel to rotate faster than the other, ensuring that torque is transferred to the wheel with better traction. This allows the wheels to rotate at different speeds, preventing tire scrubbing and providing smooth cornering.

6. Limited-Slip and Locking Differentials:

In certain differential systems, such as limited-slip differentials or locking differentials, additional mechanisms are incorporated to enhance traction and power distribution. Limited-slip differentials use clutch packs or friction plates to provide a predetermined amount of resistance, allowing some speed differentiation between the wheels while still transferring power. Locking differentials, on the other hand, lock the side gears together, ensuring equal torque distribution to both wheels, regardless of traction conditions.

7. Differential Types:

There are various types of differentials, including open differentials, limited-slip differentials, electronic differentials, torque vectoring differentials, and more. Each type has its own mechanisms and technologies to distribute power between the wheels effectively, depending on the vehicle’s requirements and driving conditions.

In summary, a differential gear distributes power between the wheels by utilizing a system of gears, including ring and pinion gears, side gears, and spider gears. The differential action allows the wheels to rotate at different speeds during turns, ensuring smooth cornering and preventing tire scrubbing. Additional mechanisms, such as limited-slip or locking differentials, can further enhance traction and power distribution in various driving conditions.

How do differential gears contribute to traction in slippery conditions?

In slippery conditions, such as driving on ice, snow, or wet surfaces, differential gears play a crucial role in improving traction and maintaining vehicle control. Here’s a detailed explanation of how differential gears contribute to traction in slippery conditions:

- Torque Distribution: Differential gears allow torque to be distributed between the wheels on the same axle. In slippery conditions, where traction is reduced, differential gears enable power to be sent to the wheels with better grip. This distribution of torque helps maximize traction and prevent wheel spin.

- Wheel Speed Variation: In slippery conditions, the wheels on the same axle may encounter different levels of traction. For example, one wheel might be on a patch of ice while the other is on a surface with better grip. Differential gears accommodate this variation by allowing the wheels to rotate at different speeds. This wheel speed variation helps ensure that power is directed to the wheels with more traction, improving overall grip and stability.

- Slip Limitation: When one wheel loses traction and starts to slip, the other wheel with better grip can potentially receive less power due to the default behavior of an open differential. However, some differential systems employ advanced features like limited-slip differentials (LSD) or electronic traction control systems. These systems detect wheel slip and apply mechanisms to limit slip and redirect power to the wheel with better traction, effectively improving traction in slippery conditions.

- Positive Traction Devices: In some cases, differential gears can be equipped with positive traction devices such as locking differentials or electronic locking differentials. These devices lock the differential gears, forcing both wheels on the same axle to rotate at the same speed. This feature is particularly beneficial in extremely slippery conditions where maximum traction is essential. By locking the differential, these devices ensure that power is evenly distributed to both wheels, maximizing grip and traction.

- Off-Road Capability: Differential gears with advanced features like limited-slip differentials or locking differentials are commonly employed in off-road vehicles. These vehicles often encounter challenging terrain with low-traction conditions. The differential systems in these vehicles enhance off-road capability by transferring power to the wheels with the most traction, preventing wheel spin, and allowing the vehicle to navigate through difficult terrain more effectively.

In summary, differential gears contribute to traction in slippery conditions by distributing torque between wheels, accommodating wheel speed variation, limiting slip through advanced features, and offering positive traction devices. These mechanisms allow power to be directed to the wheels with better grip, improving traction, stability, and overall vehicle control in slippery conditions.

How does a differential gear help in turning a vehicle smoothly?

A differential gear plays a crucial role in enabling smooth turning of a vehicle. Here’s a detailed explanation:

When a vehicle turns, the wheels on the outside of the turn travel a greater distance compared to the wheels on the inside. This difference in distance would cause significant strain and binding in the drivetrain if all the wheels were rigidly connected. The differential gear solves this problem by allowing the wheels to rotate at different speeds during turns, resulting in smooth and controlled maneuvering.

1. Speed Differentiation:

The differential gear allows the wheels to rotate at different speeds while still receiving power from the engine. As the vehicle turns, the outer wheel covers a greater distance and needs to rotate faster than the inner wheel. The differential enables this speed differentiation by distributing torque unequally between the two wheels, allowing them to rotate at different rates.

2. Path Following:

By allowing the wheels to rotate at different speeds, the differential gear helps the vehicle follow the desired path during a turn. The outside wheel, which needs to cover a longer distance, rotates faster to maintain the vehicle’s trajectory. At the same time, the inside wheel rotates slower, preventing the vehicle from skidding or drifting wide during the turn. The differential ensures that both wheels work together to maintain stability and control throughout the turning process.

3. Smooth Power Transfer:

During a turn, the differential gear facilitates smooth power transfer to the wheels. By allowing the wheels to rotate at different speeds, the differential minimizes drivetrain stress and wheel scrubbing. This promotes smoother operation and reduces the likelihood of wheel hop or wheel slip, resulting in improved traction and overall control.

4. Reduction of Tire Wear:

The differential gear’s ability to differentiate wheel speeds during turns helps reduce tire wear. If the wheels were rigidly connected, they would experience excessive scrubbing and wear during turning maneuvers. The differential allows the wheels to rotate at different speeds, minimizing tire scrubbing and promoting more even tire wear. This contributes to longer tire life and better overall performance.

5. Enhanced Maneuverability:

By enabling smooth turning, the differential gear enhances the maneuverability of a vehicle. It allows for precise and controlled steering inputs, making it easier to navigate corners, curves, and tight spaces. The differential’s role in differentiating wheel speeds ensures that the vehicle can execute turns smoothly and responsively, enhancing the overall driving experience.

In summary, the differential gear helps in turning a vehicle smoothly by allowing the wheels to rotate at different speeds during turns. This speed differentiation enables the vehicle to follow the desired path, facilitates smooth power transfer, reduces tire wear, and enhances maneuverability. The differential’s ability to accommodate varying wheel speeds ensures that the vehicle can navigate turns with improved stability, control, and comfort.

editor by CX 2023-12-06