Product Description

Key attributes

Other attributes

Applicable Industries

Manufacturing Plant, Construction works , Energy & Mining

Weight (KG)

3000

Showroom Location

None

Video outgoing-inspection

Provided

Machinery Test Report

Provided

Marketing Type

Ordinary Product

Warranty of core components

Not Available

Core Components

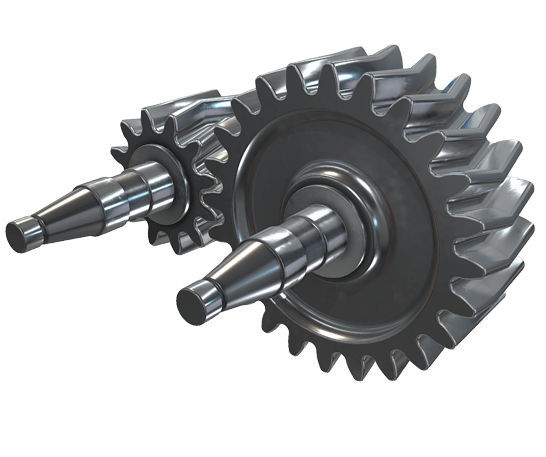

Gear, Ring Gear

Place of Origin

ZheJiang , China

Condition

New

Warranty

1year

Shape

Ring Gear

Standard or Nonstandard

Nonstandard

Tooth Profile

Helical Gear,spur gear

Material

Steel

Processing

Forging

Pressure Angle

custom

Brand Name

TS

Product Name

Large Ring Gear

Module No.

5-180

Process

Milling,hobbing

Surface treatment

as request

Heat treatment

Q&T

Application

Industry machinery,transmission equipment

Standard

DIN ANSI ISO

Certificate

ISO

OEM Service

YES

Delivery time

15-60days

Packaging and delivery

Packaging Details

Package adapting to CHINAMFG transport

Port

ZheJiang ,HangZhou

Supply Ability

Supply Ability

5 Piece/Pieces per Month

OUR WORKSHOPS

OUR EQUIPMENTS

Technology Process

|

Material |

Carbon steel,Alloy steel |

||

|

Structure |

Forging,casting |

||

|

Type of gear |

spur gear,helical gear,Planetary Gear |

||

|

Heat treatment |

Quenching and tempering |

||

|

Process |

forging, rough machining, QT, finish machining |

||

|

Main equipments |

hobbing,CNC machine |

||

|

Module |

up to 200 |

||

|

Precision of gear |

Grinding ISO Grade 5-7 & Hobbing ISO Grade 8-9 |

||

|

Inspection |

Raw material inspection, UT,physical property test,dimension inspect |

||

|

Application |

Mining machinery, mill, kiln and other equipment |

||

OUR CERTIFICATE

OUR CUSTOMER FEEDBACK

CONTACT

| Application: | Industry |

|---|---|

| Hardness: | Hb190-Hb300 |

| Gear Position: | External Gear |

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Steel |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do you choose the right size herringbone gear for your application?

Choosing the right size herringbone gear for your application involves considering several factors and performing engineering calculations. Here’s a detailed explanation of the steps involved in selecting the appropriate size herringbone gear:

- Determine the Application Requirements: Start by understanding the specific requirements of your application. Consider factors such as the input and output speeds, torque loads, power requirements, duty cycle, and operating conditions. Determine the desired service life, efficiency, and reliability expectations for the gear system.

- Calculate the Gear Ratios: Determine the required gear ratios based on the speed and torque requirements of your application. Gear ratios define the relationship between the rotational speeds and torques of the input and output shafts. Select appropriate gear ratios that fulfill the desired performance objectives.

- Calculate the Load and Torque: Estimate the maximum load and torque that the herringbone gear will experience during operation. Consider both static and dynamic loads, shock loads, and any potential overload conditions. Calculate the required torque capacity of the gear system based on these load considerations.

- Consider the Size and Space Constraints: Evaluate the available space and size constraints in your application. Measure the available distance for gear installation, including the gear’s diameter, width, and axial length. Consider any restrictions on the gear’s physical dimensions and ensure that the selected gear size fits within the available space.

- Determine the Gear Module: The gear module is a parameter that defines the size and number of gear teeth. Calculate the gear module based on the desired gear ratios, torque capacity, and available space. The gear module is typically determined by considering a balance between gear tooth strength, contact ratio, and manufacturing feasibility.

- Perform Gear Design Calculations: Utilize standard gear design formulas and calculations to determine the required number of gear teeth, pitch diameter, helix angles, and other gear dimensions. Consider factors such as gear tooth strength, contact ratio, tooth profile optimization, and gear manufacturing standards. These calculations ensure that the selected gear size can handle the anticipated loads and provide reliable performance.

- Consult Manufacturers and Standards: Consult gear manufacturers, industry standards, and guidelines to ensure compliance with best practices and safety requirements. Manufacturers can provide technical expertise, recommend suitable gear sizes, and offer guidance on material selection, heat treatment processes, and gear quality standards.

- Consider Cost and Availability: Evaluate the cost implications and availability of the selected gear size. Consider factors such as material costs, manufacturing complexity, lead times, and the overall economic feasibility of the gear system. Balance the desired performance with cost considerations to arrive at an optimal gear size.

It’s important to note that selecting the right size herringbone gear requires expertise in gear design and engineering. If you lack the necessary knowledge, it is advisable to consult with experienced gear engineers or manufacturers who can assist in the selection process.

In summary, choosing the right size herringbone gear involves determining the application requirements, calculating gear ratios and torque loads, considering size constraints, determining the gear module, performing gear design calculations, consulting manufacturers and standards, and considering cost and availability. Following these steps ensures that the selected herringbone gear size meets the specific needs of your application and provides reliable and efficient operation.

How do you prevent backlash and gear play in a herringbone gear mechanism?

Preventing backlash and gear play is crucial in a herringbone gear mechanism to ensure accurate and efficient power transmission. Here’s a detailed explanation of methods to prevent backlash and gear play in a herringbone gear mechanism:

- Precision Manufacturing: Backlash and gear play can be minimized by ensuring precise manufacturing of the herringbone gears. This involves maintaining tight tolerances during gear machining, tooth profiling, and gear assembly. High-quality manufacturing processes help achieve proper gear tooth engagement and minimize any gaps that can lead to backlash.

- Proper Gear Alignment: Accurate alignment of the herringbone gears is essential to reduce backlash. Misalignment can result in uneven load distribution and improper gear meshing, leading to increased gear play. Proper alignment should be ensured during the initial installation and periodically checked during maintenance to maintain optimal gear performance.

- Optimal Tooth Contact: Maximizing tooth contact between the herringbone gears can help reduce backlash. This can be achieved by adjusting the gear position, gear meshing depth, and gear tooth profile. By optimizing tooth contact, the gears are more tightly engaged, minimizing any free play or backlash between the gear teeth.

- Preload or Gear Meshing Pre-Tensioning: Applying a small amount of preload or pre-tensioning in the herringbone gear mechanism can help minimize backlash. This can be achieved by using spring-loaded components, such as thrust bearings or Belleville washers, to exert a slight force on the gears, ensuring continuous contact and reducing any play between the gear teeth.

- Appropriate Lubrication: Proper lubrication of the herringbone gears is essential to reduce friction, wear, and backlash. Using the right type and amount of lubricant helps maintain smooth gear operation, ensuring optimal gear meshing and minimizing gear play. Regular lubrication maintenance is necessary to prevent excessive wear and maintain proper lubrication film thickness.

- Stiff Gearbox Design: A stiff and rigid gearbox design can help minimize gear play and backlash. By reducing any flexing or deflection within the gearbox components, the herringbone gears can maintain their proper alignment and engagement, reducing the potential for backlash. Robust housing structures, rigid shafts, and appropriate bearing support contribute to a stiff gearbox design.

- Periodic Maintenance and Inspection: Regular maintenance and inspection procedures are crucial for identifying and addressing any potential issues that can lead to backlash or gear play in a herringbone gear mechanism. This includes checking gear alignment, lubrication condition, gear tooth wear, and any signs of damage or misalignment. Any detected problems should be promptly resolved to maintain optimal gear performance.

Implementing these prevention methods can help minimize backlash and gear play, ensuring accurate and efficient power transmission in a herringbone gear mechanism. It is important to consider the specific operating conditions, load requirements, and system design factors when applying these methods to achieve the best performance from herringbone gears.

What are the applications of herringbone gears?

Herringbone gears, also known as double helical gears, find applications in various industries due to their unique design and advantages. Here’s a detailed explanation of the applications of herringbone gears:

- Power Transmission Systems: Herringbone gears are commonly used in power transmission systems that require efficient torque transfer and smooth operation. They are employed in gearboxes, drivetrains, and speed reducers where high torque and bidirectional power transmission are critical.

- Heavy Machinery: Herringbone gears are found in heavy machinery such as construction equipment, mining machinery, and industrial machinery. These gears can handle large loads and provide reliable torque transmission, making them suitable for applications that involve heavy-duty operations.

- Oil and Gas Industry: The oil and gas industry extensively uses herringbone gears in equipment like pumps, compressors, and turbines. These gears are capable of handling high torque requirements and provide reliable performance in demanding environments.

- Marine Propulsion Systems: Herringbone gears are utilized in marine propulsion systems, including ship propulsion drives and propeller shaft arrangements. Their ability to transmit high torque efficiently and smoothly makes them ideal for marine applications.

- High-Speed Gearboxes: Herringbone gears are employed in high-speed gearboxes where torque is transmitted at high rotational speeds. They are used in applications such as wind turbine gearboxes, aerospace systems, and high-performance automotive transmissions.

- Metalworking Machinery: Herringbone gears are utilized in metalworking machinery, such as milling machines, lathes, and gear cutting machines. These gears provide precise and reliable power transmission, enabling the machinery to perform various machining operations with accuracy.

- Railway Systems: Herringbone gears find applications in railway systems, particularly in locomotives and rolling stock. They facilitate efficient power transfer and contribute to smooth and reliable train operation.

- Printing Presses: Herringbone gears are used in printing presses to transmit power between different components of the press. Their ability to minimize vibrations and noise is advantageous in printing applications that require precision and high-quality printing results.

- Steel Mills: Herringbone gears are employed in steel mills for various applications, including rolling mills, heavy-duty cranes, and gear couplings. These gears withstand the demanding conditions of steel manufacturing, such as high loads, vibrations, and harsh environments.

These are just a few examples of the applications of herringbone gears. Their unique tooth design, load-carrying capacity, bidirectional power transmission capability, and smooth operation make them suitable for a wide range of industries and applications that require efficient and reliable torque transmission.

editor by CX 2023-11-28