Product Description

The Advantage of Powder Metallurgy Process

1.Cost effective: The final products can be compacted with powder metallurgy method, and no need or can shorten the processing of machine. It can save material greatly and reduce the production cost.

2.Complex shapes: Powder metallurgy allows to obtaining complex shapes directly from the compacting tooling, without any machining operation, like teeth, splines, profiles, frontal geometries, etc.

3.High precision: Achievable tolerances in the perpendicular direction of compacting are typically IT 8-9 as sintered; improvable up to IT 5-7 after sizing. Additional machining operations can improve the precision.

4.Self-lubrication: The interconnected porosity of the material can be filled with oils, obtaining, and then a self-lubricating bearing; the oil provides constant lubrication between bearing and shaft, and the system does not need any additional external lubricant.

5.Green technology: The manufacturing process of sintered components is certified as ecological, because the material waste is very low, the product is recyclable, and the energy efficiency is good because the material is not molten.

| Product Name | Planet Gear Used for Automobile Powder Metallurgy |

| Material | Powder metal – FD5715 |

| Technology | Powder Metallurgy – Machining |

| Standard | ISO9001 |

| Surface Treatment | High Frequency quenching, Oil impregnation |

| Process Flow | Powder mixing – Forming – Sintering – Oil impregnation – Sizing -Ultrasonic Cleaning – Steam Oxidation – Oil impregnation – Final inspection – Packing |

| Apperance | No Crumbling, Cracks, Exfoliation, Voids, Metal Pitting and Other Defects |

| Application | building industry machinery |

Detail:

Technology :

Workshop:

Packing:

ship:

FAQ:

Q: Do you make customized products based on our design drawings?

A: Yes, we are a professional metal fabrication supplier with experienced engineering team to make custom products according to clients’ drawings.

Q: Will my drawing be safe after you get it?

A: Yes, we won’t release your design to any third parties unless have your permission. And we can CHINAMFG the NDA before you send the drawing.

Q: What is the MOQ?

A: We don’t set MOQ, but the price will be better for the larger quantity . Besides, we are happy to make prototype or sample for clients to ensure quality standard.

Q: Whether some samples can be provided?

A: Yes, just need some sample cost, we will return it back when proceed into mass production.

Q: How to deal with the parts received when they are found to be in poor quality?

A: Please rest assured that all our products are QC inspected and accepted with inspection report before delivery and generally there will no non-conformance: in case of non- conformance, please contact us immediately, take some pictures, we will check on the problems and have them reworked or repaired at the first time , the resulting transportation costs will be our side.

| Condition: | New |

|---|---|

| Certification: | CE, ISO9001 |

| Standard: | DIN, ASTM |

| Customized: | Customized |

| Material: | Sintered Metallurgy |

| Application: | Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

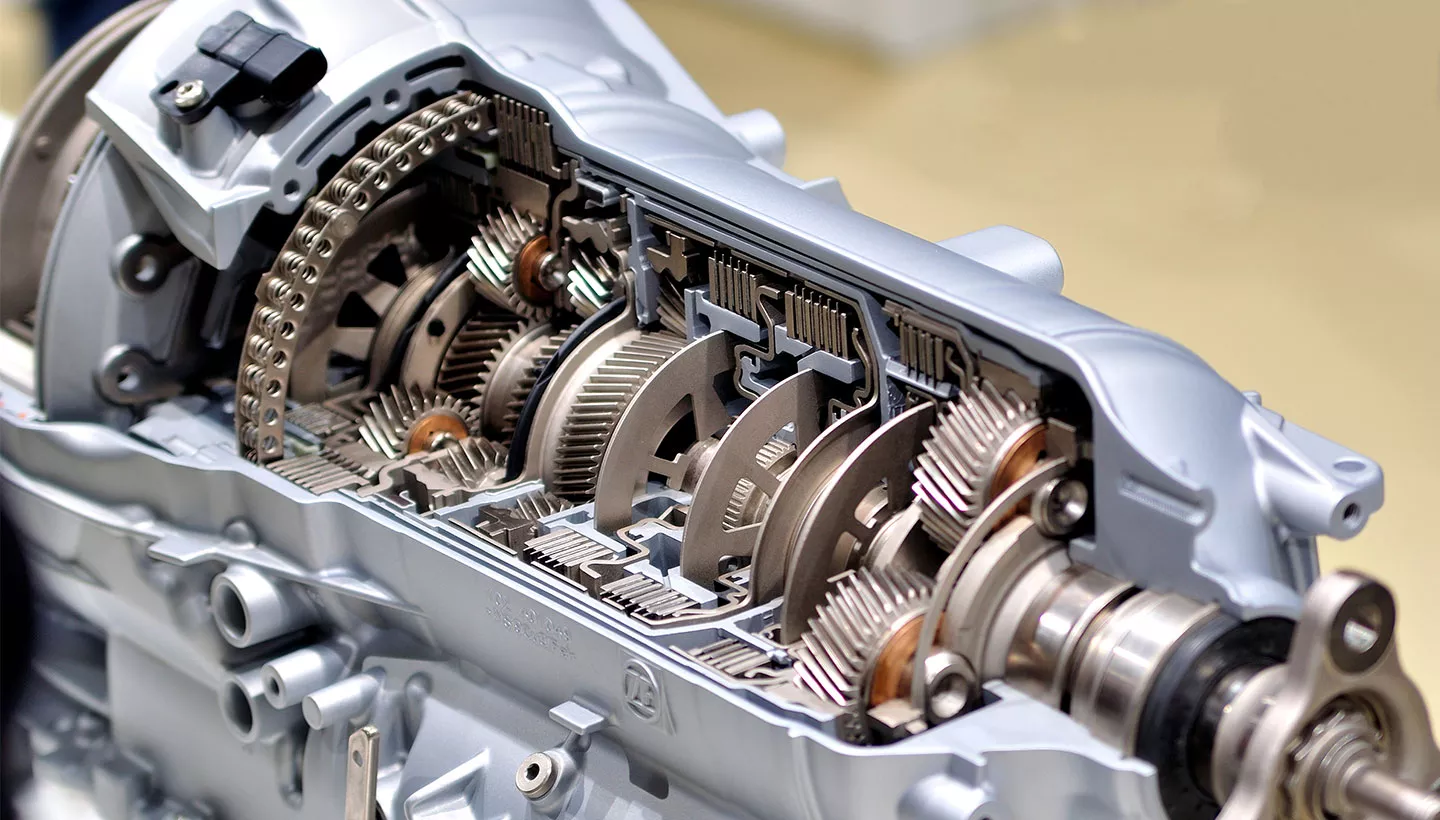

How does a synchronized transmission system operate in manual cars?

A synchronized transmission system is a key component of manual transmissions in cars. Here’s a detailed explanation:

1. Purpose of Synchronized Transmission:

The purpose of a synchronized transmission system is to facilitate smooth and effortless shifting between gears in a manual transmission. It ensures that the rotational speeds of the input shaft (connected to the engine) and the output shaft (connected to the wheels) match before engaging the selected gear.

2. Synchronizer Rings:

The synchronized transmission system utilizes synchronizer rings, also known as synchro rings or blockers, to achieve synchronization. These rings are mounted on the transmission’s main shaft and are responsible for equalizing rotational speeds between the input and output shafts.

3. Cone Clutch Design:

The synchronizer rings feature a cone clutch design. When the driver selects a gear using the gear lever, the synchro ring corresponding to that gear slides over the gear’s dog teeth on the output shaft. The synchro ring and the dog teeth have matching cone-shaped surfaces.

4. Friction and Synchronization:

As the synchro ring engages with the dog teeth, it creates friction between the cone surfaces. This friction helps equalize the speeds of the input and output shafts. The synchro ring synchronizes the rotational speeds of the selected gear and the output shaft, allowing for smooth gear engagement.

5. Blocking and Engagement:

Once the rotational speeds are synchronized, the driver can easily engage the selected gear by pressing the clutch pedal and shifting the gear lever. The synchro rings facilitate the engagement by temporarily blocking the dog teeth on the output shaft, allowing the gears to mesh smoothly without grinding or clashing.

6. Double-Clutching:

In some older manual transmissions or vehicles with non-synchronized transmissions, a technique called double-clutching is required for smooth gear engagement. Double-clutching involves an additional step of disengaging the clutch after shifting out of the current gear, briefly engaging the clutch to match the engine speed with the transmission speed, and then shifting into the desired gear while the clutch is disengaged again. This technique is not necessary in modern synchronized transmissions.

7. Benefits of Synchronized Transmission:

The synchronized transmission system offers several benefits, including:

- Smooth shifting: The synchronizer rings enable seamless and smooth gear shifts, enhancing the overall driving experience.

- Reduced wear and tear: By equalizing rotational speeds before gear engagement, the synchronized transmission system minimizes wear and tear on the gears, synchro rings, and other transmission components.

- User-friendly operation: Synchronized transmissions are user-friendly, allowing drivers to shift gears effortlessly without the need for complex techniques like double-clutching.

In summary, a synchronized transmission system in manual cars utilizes synchronizer rings with cone clutch design to synchronize the rotational speeds of the input and output shafts. This enables smooth gear engagement and seamless shifting between gears, providing a user-friendly and efficient driving experience.

How does a dual-clutch transmission (DCT) enhance the driving experience?

A dual-clutch transmission (DCT) enhances the driving experience in several ways. Here’s a detailed explanation:

1. Quick and Smooth Gear Shifts:

A DCT utilizes two separate clutches, one for odd-numbered gears and another for even-numbered gears. This dual-clutch setup allows for quick and seamless gear shifts without interrupting power delivery. While one clutch is engaged with the current gear, the other clutch pre-selects the next gear, resulting in near-instantaneous shifts. This quick and smooth shifting enhances acceleration and provides a more engaging driving experience.

2. Continuous Power Delivery:

Since a DCT can shift gears without the need for a torque converter (as in automatic transmissions), there is minimal power loss during gear changes. The power transfer from the engine to the wheels remains uninterrupted, resulting in improved performance and responsiveness. This continuous power delivery contributes to a more dynamic driving experience.

3. Enhanced Fuel Efficiency:

DCTs are designed to optimize fuel efficiency by reducing power losses and maximizing engine performance. The precise and efficient gear changes of a DCT help keep the engine operating in its optimal power band, resulting in improved fuel economy compared to traditional automatic transmissions.

4. Manual Control and Sporty Driving:

Many DCT-equipped vehicles offer manual control modes, such as paddle shifters or a manual shift gate. These modes allow the driver to manually select gears, providing a more involved and sporty driving experience. The ability to control gear changes enhances driver engagement and allows for greater control over the vehicle’s performance.

5. Versatility and Adaptability:

DCTs can adapt to different driving conditions and driver preferences. They often feature multiple driving modes, such as “Normal,” “Sport,” or “Eco,” which adjust shift points, throttle response, and other parameters to suit various driving styles. This versatility allows drivers to tailor the transmission’s behavior to their preferences, whether they prioritize performance, fuel efficiency, or comfort.

6. Suitable for Performance Vehicles:

DCTs are commonly used in high-performance and sporty vehicles due to their ability to provide lightning-fast gear changes and precise control. The rapid and seamless shifts of a DCT contribute to improved acceleration, faster lap times, and enhanced overall performance.

In summary, a dual-clutch transmission (DCT) enhances the driving experience through quick and smooth gear shifts, continuous power delivery, improved fuel efficiency, manual control options, adaptability to different driving conditions, and suitability for performance-oriented vehicles. These features contribute to a more engaging, responsive, and enjoyable driving experience for enthusiasts and drivers seeking a balance between performance and everyday usability.

What are the common types of automobile transmissions available?

There are several common types of automobile transmissions used in vehicles. Here’s a detailed explanation:

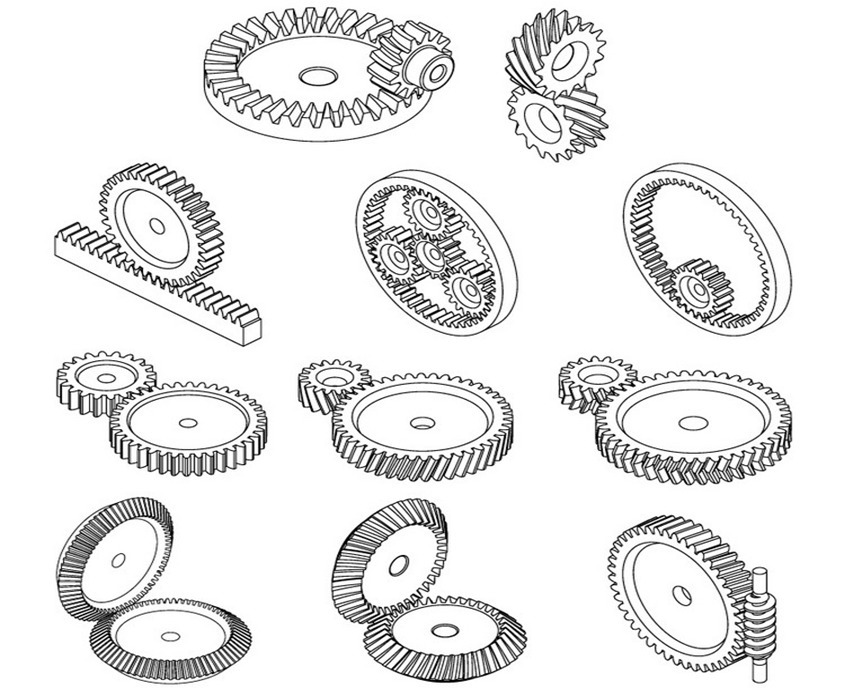

1. Manual Transmission: Manual transmissions, also known as “stick shift” or “standard” transmissions, require the driver to manually shift gears using a clutch pedal and gearshift lever. They typically have a set of forward gears, including first, second, third, fourth, and fifth (or sixth) gears, along with a reverse gear. Manual transmissions offer direct control over gear selection and are often preferred by enthusiasts for their engagement and control.

2. Automatic Transmission: Automatic transmissions use a torque converter and a complex system of planetary gears to automatically shift gears without driver intervention. They are the most common type of transmission in modern vehicles. Automatic transmissions provide smooth and convenient operation as they automatically select the appropriate gear ratio based on factors such as vehicle speed, engine load, and driver input. They typically offer “Drive” (D) mode for normal driving and may include additional modes like “Sport” (S) or “Economy” (E) for different driving preferences.

3. Continuously Variable Transmission (CVT): CVT is a type of automatic transmission that offers an infinite number of gear ratios within a specific range. Instead of using traditional gears, CVTs use a system of belts or chains and pulleys to provide seamless gear ratio changes. CVTs are known for their smoothness and fuel efficiency as they keep the engine operating at its most efficient RPM. They are commonly found in smaller vehicles and hybrid cars.

4. Dual-Clutch Transmission (DCT): DCT combines features of both manual and automatic transmissions. It uses two separate clutches for odd and even gears, allowing for quick and smooth gear shifts without interrupting power delivery. One clutch handles the current gear, while the other anticipates and prepares the next gear for engagement. DCTs provide fast and precise gear changes, making them popular in high-performance and sporty vehicles.

5. Automated Manual Transmission (AMT): AMT, also known as “Semi-Automatic Transmission” or “Clutchless Manual Transmission,” is essentially a manual transmission with automated clutch and gear shifting. Unlike traditional automatic transmissions, AMTs do not have a torque converter. Instead, they use actuators to control the clutch and gear selection based on the driver’s input or pre-programmed settings. AMTs are cost-effective alternatives to conventional automatic transmissions and are commonly found in entry-level or budget-friendly vehicles.

6. Sequential Manual Transmission (SMG) and Dual-Clutch Sequential Transmission: Sequential transmissions are commonly used in high-performance and racing vehicles. They allow for quick and precise sequential gear shifting without the need for a clutch pedal. SMGs use a single clutch, while dual-clutch sequential transmissions operate similarly to DCTs, with two clutches for improved performance and faster gear changes. Sequential transmissions provide rapid gear shifts, enhanced control, and are often controlled via paddle shifters mounted on the steering wheel.

These are some of the most common types of automobile transmissions available. Each type has its own advantages and characteristics, catering to different driving preferences, performance requirements, and fuel efficiency goals.

editor by CX 2023-10-31