Product Description

Product Parameters

| product name | Reliable Quality Stainless Steel Spur Gear Customized for New Energy Automobile Industry with SGS Certification |

| material | stainless steel , iron , aluminum ,bronze ,carbon steel ,brass , nylon etc . |

| size | ISO standard ,customer requirements |

| BORE | Finished bore, Pilot Bore, Special request |

| surface treatment | Carburizing and Quenching,Tempering ,Tooth suface high quenching Hardening,Tempering |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding…… |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001 |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping ,gear accuracy testing |

| Applications | Toy, Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment,daily living equipment, electronic sports equipment, , sanitation machinery, market/ hotel equipment supplies, etc. |

| Testing Equipment | Rockwell hardness tester 500RA, Double mesh instrument HD-200B & 3102,Gear measurement center instrument CNC3906T and other High precision detection equipments |

Company Profile

Application Field

FAQ

1. why should you buy products from us not from other suppliers?

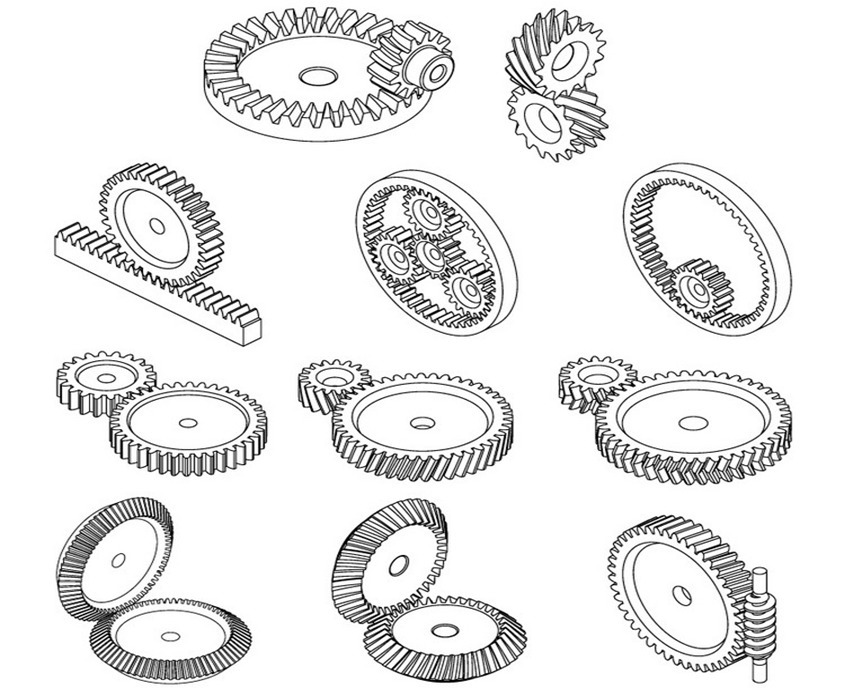

We are a 32 year-experience manufacturer on making the gear, specializing in manufacturing varieties of gears, such as helical gear ,bevel gear ,spur gear and grinding gear, gear shaft, timing pulley, rack, , timing pulley and other transmission parts .

2. what services can we provide?

Accepted Delivery Terms: Fedex,DHL,UPS;

Accepted Payment Currency:USD,EUR,HKD,GBP,CNY;

Accepted Payment Type: T/T,L/C,PayPal,Western Union;

Language Spoken:English,Chinese

3. how can we guarantee quality?

1 .Always a pre-production sample before mass production;

2 .Always final Inspection before shipment;

3 .We have high-precision CNC gear grinding machine, high-speed CNC gear hobbing machine, CNC gear shaping machine, CNC lathe, CNC machining center, various grinding machines, universal gear measuring instrument, heat treatment and other advanced processing equipment.

4 . We have a group of experienced technical workers, more than 90% of the workers have more than 10 years of work experience in this factory, can accurately control the manufacturing of products and customer needs. We regularly train our employees to ensure that we can produce high-precision and high-quality products that are more in line with our customers’ needs.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the advantages and disadvantages of automatic and manual transmissions?

Automatic and manual transmissions each have their own set of advantages and disadvantages. Here’s a detailed explanation:

Automatic Transmissions:

Advantages:

- Ease of Use: Automatic transmissions are easier to operate since they do not require the driver to manually engage gears. This makes them more convenient, especially in heavy traffic or during long commutes.

- Smooth Shifting: Automatic transmissions provide smooth and seamless gear shifts, as the shifting process is controlled by the vehicle’s computer system. This results in a comfortable driving experience.

- Improved Fuel Efficiency: Modern automatic transmissions often feature advanced technologies such as continuously variable transmissions (CVT) or dual-clutch transmissions (DCT), which can optimize fuel efficiency by selecting the most appropriate gear ratio for the driving conditions.

- Reduced Driver Fatigue: With automatic transmissions, drivers can focus more on the road and other aspects of driving, as they don’t need to manually shift gears. This can reduce driver fatigue, especially during long journeys.

Disadvantages:

- Higher Cost: Automatic transmissions tend to be more expensive to manufacture and repair compared to manual transmissions, which can result in higher vehicle purchase prices and maintenance costs.

- Less Control: Some driving enthusiasts prefer manual transmissions because they offer more control over gear selection, allowing for a more engaging driving experience. Automatic transmissions, on the other hand, limit the driver’s ability to choose specific gear ratios.

- Lower Power Transfer Efficiency: Automatic transmissions can have slightly lower power transfer efficiency compared to manual transmissions, which means that some engine power is lost during the transmission of power from the engine to the wheels.

Manual Transmissions:

Advantages:

- Greater Control: Manual transmissions provide the driver with full control over gear selection, allowing for precise shifts and the ability to match engine RPM to driving conditions. This control can enhance the driving experience, especially for those who enjoy a more engaged and sporty driving style.

- Improved Power Transfer Efficiency: Manual transmissions generally have higher power transfer efficiency compared to automatic transmissions. This means that a greater percentage of engine power reaches the wheels, resulting in better acceleration and responsiveness.

- Lower Maintenance Costs: Manual transmissions are typically less complex and have fewer components compared to automatic transmissions. Consequently, they often require less maintenance and can be more cost-effective to repair.

Disadvantages:

- Requires Skill: Operating a manual transmission requires learning how to engage gears, coordinate clutch and throttle control, and shift smoothly. This can be challenging for drivers who are not accustomed to manual transmissions or prefer a more relaxed driving experience.

- Increased Physical Effort: Maneuvering a clutch pedal in stop-and-go traffic or during long drives can be physically tiring, especially in situations that require frequent gear changes.

- Steeper Learning Curve: Learning to drive a manual transmission vehicle effectively takes time and practice. It requires developing a feel for the clutch engagement point and mastering the coordination between the clutch, gear lever, and accelerator pedal.

Ultimately, the choice between automatic and manual transmissions depends on personal preference, driving conditions, and driving style. Automatic transmissions offer convenience and ease of use, while manual transmissions provide greater control and a more engaging driving experience.

What is a continuously variable transmission (CVT) and how does it work in cars?

A continuously variable transmission (CVT) is a type of automatic transmission that provides an infinite number of gear ratios within a specific range. Here’s a detailed explanation of how it works:

In a traditional transmission, gears of different sizes are used to achieve different gear ratios. These gears have fixed ratios, and the transmission shifts between them to adjust the speed and torque output. In contrast, a CVT uses a different mechanism to vary the gear ratios.

1. Pulleys and Belt/Chain System:

A CVT consists of two pulleys connected by a metal belt or a chain. Each pulley has two halves that can move closer together or farther apart. One pulley is connected to the engine, and the other is connected to the wheels.

2. Variable Pulley Diameter:

The pulleys in a CVT have variable diameters. As the pulley halves move closer together, the effective diameter decreases, and as they move farther apart, the effective diameter increases. This adjustment of the pulley diameters allows for continuous variation of the gear ratio.

3. Belt/Chain Movement:

The metal belt or chain runs between the two pulleys. When the effective diameter of one pulley decreases, the belt or chain moves towards the larger diameter on the other pulley. As a result, the contact point on the pulleys changes, altering the effective gear ratio.

4. Hydraulic or Electronic Control:

To control the movement of the pulleys, a CVT uses a hydraulic or electronic control system. This system monitors various factors, such as vehicle speed, engine load, throttle input, and acceleration demands, to determine the optimal gear ratio. It then adjusts the position of the pulley halves accordingly.

5. Seamless Gear Ratio Changes:

Due to the continuous variation of the pulley diameters, a CVT provides seamless gear ratio changes. It can continuously adjust the gear ratio to keep the engine operating at its most efficient RPM for a given driving condition. This flexibility allows the engine to deliver power more effectively and improves fuel efficiency.

6. “Step” or “Shift” Modes:

Some CVTs offer “step” or “shift” modes to simulate traditional gear shifting. In these modes, the CVT may have predefined ratios or “virtual” gears that mimic the feel of gear changes. This can provide a more familiar driving experience for those accustomed to traditional automatic transmissions.

CVTs are known for their smoothness and fuel efficiency. By continuously adjusting the gear ratio to match the engine’s power output and the driving conditions, a CVT helps optimize fuel consumption. They are commonly found in smaller vehicles and hybrid cars.

However, it’s worth noting that CVTs may have a different driving feel compared to traditional transmissions, as the engine RPM can remain relatively constant during acceleration. Some drivers may prefer the stepped gear changes of conventional transmissions for a more engaging driving experience.

“`

What are the common types of automobile transmissions available?

There are several common types of automobile transmissions used in vehicles. Here’s a detailed explanation:

1. Manual Transmission: Manual transmissions, also known as “stick shift” or “standard” transmissions, require the driver to manually shift gears using a clutch pedal and gearshift lever. They typically have a set of forward gears, including first, second, third, fourth, and fifth (or sixth) gears, along with a reverse gear. Manual transmissions offer direct control over gear selection and are often preferred by enthusiasts for their engagement and control.

2. Automatic Transmission: Automatic transmissions use a torque converter and a complex system of planetary gears to automatically shift gears without driver intervention. They are the most common type of transmission in modern vehicles. Automatic transmissions provide smooth and convenient operation as they automatically select the appropriate gear ratio based on factors such as vehicle speed, engine load, and driver input. They typically offer “Drive” (D) mode for normal driving and may include additional modes like “Sport” (S) or “Economy” (E) for different driving preferences.

3. Continuously Variable Transmission (CVT): CVT is a type of automatic transmission that offers an infinite number of gear ratios within a specific range. Instead of using traditional gears, CVTs use a system of belts or chains and pulleys to provide seamless gear ratio changes. CVTs are known for their smoothness and fuel efficiency as they keep the engine operating at its most efficient RPM. They are commonly found in smaller vehicles and hybrid cars.

4. Dual-Clutch Transmission (DCT): DCT combines features of both manual and automatic transmissions. It uses two separate clutches for odd and even gears, allowing for quick and smooth gear shifts without interrupting power delivery. One clutch handles the current gear, while the other anticipates and prepares the next gear for engagement. DCTs provide fast and precise gear changes, making them popular in high-performance and sporty vehicles.

5. Automated Manual Transmission (AMT): AMT, also known as “Semi-Automatic Transmission” or “Clutchless Manual Transmission,” is essentially a manual transmission with automated clutch and gear shifting. Unlike traditional automatic transmissions, AMTs do not have a torque converter. Instead, they use actuators to control the clutch and gear selection based on the driver’s input or pre-programmed settings. AMTs are cost-effective alternatives to conventional automatic transmissions and are commonly found in entry-level or budget-friendly vehicles.

6. Sequential Manual Transmission (SMG) and Dual-Clutch Sequential Transmission: Sequential transmissions are commonly used in high-performance and racing vehicles. They allow for quick and precise sequential gear shifting without the need for a clutch pedal. SMGs use a single clutch, while dual-clutch sequential transmissions operate similarly to DCTs, with two clutches for improved performance and faster gear changes. Sequential transmissions provide rapid gear shifts, enhanced control, and are often controlled via paddle shifters mounted on the steering wheel.

These are some of the most common types of automobile transmissions available. Each type has its own advantages and characteristics, catering to different driving preferences, performance requirements, and fuel efficiency goals.

editor by Dream 2024-04-30