Product Description

Our company can process star wheel according to the requirements, can mass production of star wheel, welcome to map processing star wheel.

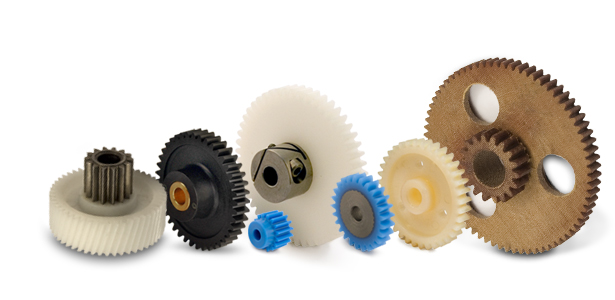

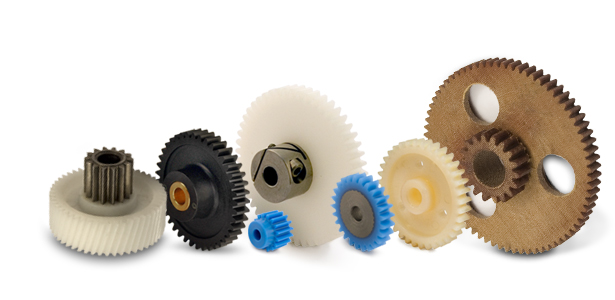

Our products mainly include: beer, beverage and food processing machinery such as network chain, transmission chain plate, sprocket, bent rail, screw, gear, roller, pad, guide rail, sleeve, pulley and related mechanical accessories. The engineering plastic products produced have excellent mechanical properties, strength, stiffness, hardness and toughness are high, and has light weight, wear resistance, aging resistance, self-lubrication and good mechanical processing performance. Widely used in packaging, beverage, food, electronics, textile, automation and other manufacturing industries.HangZhou CHINAMFG Automation Industry Co., Ltd. specializes in the production and sales of ultra-high molecular polyethylene plate, rod, extrusion wear-resistant bar, guardrail, chain guide rail, screw, magnetic bending straight rail, bottle flipper, bottle hanging bar and other products.

Our company mainly uses raw materials imported from Germany to produce plate, bar, pipe, film and other basic materials as well as the production of chain guide rail, screw, bend rail, cushion bar, guardrail, wear-resistant bar and other special-shaped parts products, our company has a domestic leading level of plate production line, three-station four-layer production line 6, German import production line 2, continuous molding production line 40. There are 60 patented extrusion production lines, 6 special extrusion production lines, 6 special-shaped molding machines, more than 20 CNC machining centers and various processing equipment.

Our products have excellent quality, products with high wear resistance, self-lubrication, high impact resistance, corrosion resistance and other properties, we are committed to making excellent durable products, in-depth cooperation with many of the world’s top 500 enterprises, cooperate with enterprises to develop excellent products and parts, welcome new and old customers to inquire, jointly develop contracts. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard: | GB |

|---|---|

| Material: | UHMWPE |

| Surface Treatment: | CNC Machining |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can plastic gears be used in food and beverage processing machinery?

Plastic gears can be used in food and beverage processing machinery in certain applications. Here’s a detailed explanation of their suitability:

Plastic gears offer several advantages that make them a viable choice for certain food and beverage processing machinery applications:

- Corrosion Resistance: Many plastic materials, such as certain types of polypropylene (PP) or polyethylene (PE), exhibit excellent resistance to corrosion and chemical attack. This makes them suitable for use in food and beverage processing environments where exposure to acidic or alkaline substances, cleaning agents, or food ingredients is common.

- Hygienic Properties: Plastic gears can be designed to have smooth surfaces without any cracks, crevices, or pores, which can harbor bacteria or contaminants. This makes them easier to clean and sterilize, promoting hygienic conditions in food and beverage processing machinery.

- Lightweight: Plastic gears are generally lighter than metal gears, which can be advantageous in applications where weight reduction is desired. The reduced weight can simplify machinery design, reduce energy consumption, and ease handling during maintenance or equipment assembly.

- Noise Reduction: Plastic gears, with their inherent damping characteristics, can help reduce noise levels in food and beverage processing machinery. This is particularly beneficial in settings where noise control is crucial for maintaining a comfortable working environment.

- Non-Toxicity: Food-grade plastic materials, such as certain types of polyethylene terephthalate (PET) or polytetrafluoroethylene (PTFE), are approved for contact with food and beverages. These materials comply with regulatory standards for food safety and do not leach harmful substances into the processed products.

- Design Flexibility: Plastic gears offer greater design flexibility compared to metal gears. They can be molded into complex shapes and incorporate features such as self-lubrication, noise reduction, or specific gear profiles to optimize performance for food and beverage processing applications.

However, it’s important to note that there are certain considerations and limitations when using plastic gears in food and beverage processing machinery:

- Operating Conditions: Plastic gears have temperature limitations and may not be suitable for applications involving high temperatures or extreme temperature fluctuations. It’s essential to select plastic materials that can withstand the specific temperature range of the processing environment.

- Load Requirements: Plastic gears typically have lower load-bearing capacities compared to metal gears. They may not be suitable for heavy-duty applications that require withstanding high torque or significant forces. Careful consideration should be given to the torque and load requirements of the specific machinery application.

- Application-Specific Requirements: Some food and beverage processing machinery applications may have unique requirements, such as high-speed operation, abrasive ingredients, or frequent cleaning cycles. It’s crucial to assess whether plastic gears can meet these specific requirements and evaluate the need for additional reinforcements or modifications.

Overall, plastic gears can be successfully used in food and beverage processing machinery for suitable applications, offering benefits such as corrosion resistance, hygienic properties, lightweight design, noise reduction, and compliance with food safety standards. However, proper material selection, design considerations, and a thorough understanding of the application’s requirements are important to ensure the reliable and safe operation of the machinery.

Can plastic gears be used in automotive applications?

Yes, plastic gears can be used in automotive applications. Here’s a detailed explanation:

Plastic gears have several advantages that make them suitable for certain automotive applications. They are lightweight, have good wear resistance, offer design flexibility, and can operate with low noise levels. However, it’s important to consider the specific requirements and limitations of automotive applications before using plastic gears.

1. Non-load Bearing Applications: Plastic gears are commonly used in non-load bearing applications within automotive systems. These include applications such as instrument clusters, HVAC systems, seat adjustments, and interior components. In these cases, the gears are subjected to relatively low loads and can effectively perform their functions while offering benefits such as weight reduction and cost efficiency.

2. Auxiliary Systems: Plastic gears can also be used in auxiliary systems of vehicles, such as windshield wipers, window regulators, and sunroof mechanisms. These systems typically operate at lower loads and speeds compared to primary powertrain components. Plastic gears can provide reliable performance in these applications while contributing to weight reduction and improved fuel efficiency.

3. Noise and Vibration: Plastic gears have inherent damping properties that can help reduce noise and vibration in automotive applications. This is particularly advantageous in areas where noise reduction is a priority, such as electric window mechanisms or HVAC systems. Plastic gears can contribute to a quieter and more comfortable driving experience.

4. Design Flexibility: Plastic gears offer design flexibility, allowing for complex shapes and customization to meet specific automotive requirements. They can be molded with precision to achieve intricate gear profiles and optimize gear performance. The flexibility in design can lead to improved efficiency, reduced weight, and space-saving advantages in automotive systems.

5. Material Selection: The selection of the appropriate plastic material is crucial for automotive applications. Certain plastic materials, such as engineering thermoplastics like POM (polyoxymethylene) or PA (polyamide), offer higher strength, rigidity, and wear resistance compared to standard plastics. These materials can withstand the demands of automotive environments, including temperature variations and exposure to chemicals or oils.

6. Load-Bearing Applications: While plastic gears are commonly used in non-load bearing or low-load applications within the automotive industry, they may have limitations in high-load or high-torque applications. Metal gears, such as steel or cast iron, are generally preferred for primary powertrain components such as transmissions and differential systems, where higher strength and durability are required to handle the significant loads and forces involved.

7. Environmental Considerations: Automotive applications can expose gears to various environmental factors such as temperature extremes, humidity, UV radiation, and exposure to chemicals or oils. The selected plastic material should have good resistance to these environmental conditions to ensure long-term durability and performance.

In summary, plastic gears can be successfully used in certain automotive applications, particularly in non-load bearing or low-load scenarios, as well as in auxiliary systems. They offer advantages such as weight reduction, design flexibility, and noise reduction. However, when considering the use of plastic gears in automotive applications, it’s important to carefully evaluate the specific requirements, loads, environmental conditions, and material selection to ensure optimal performance and durability.

What industries commonly use plastic gears?

Plastic gears find applications in various industries due to their unique properties and advantages. Here’s a detailed explanation of the industries that commonly use plastic gears:

- Automotive: Plastic gears are used in automotive applications such as power windows, seat adjusters, HVAC systems, windshield wipers, and various motor-driven mechanisms. Their lightweight nature, noise reduction capabilities, and corrosion resistance make them suitable for these applications.

- Consumer Electronics: Plastic gears are used in consumer electronics devices like printers, scanners, cameras, and audio equipment. Their lightweight construction, low noise generation, and design flexibility make them ideal for compact and noise-sensitive applications.

- Medical: Plastic gears are utilized in medical devices and equipment such as pumps, lab instruments, diagnostic devices, and surgical equipment. Their corrosion resistance, lubricity, and ability to be sterilized make them suitable for medical environments.

- Office Equipment: Plastic gears are commonly found in office equipment like printers, photocopiers, scanners, and shredders. Their low noise operation, lightweight construction, and cost-effectiveness make them popular choices in these applications.

- Industrial Machinery: Plastic gears are used in various industrial machinery applications, including packaging equipment, conveyor systems, material handling equipment, and small gearboxes. Their self-lubricating properties, corrosion resistance, and noise reduction capabilities make them suitable for these industrial environments.

- Toys and Games: Plastic gears are extensively used in toys, hobbyist models, and games. Their lightweight nature, cost-effectiveness, and ease of customization allow for the creation of intricate moving parts in these recreational products.

- Aerospace: Plastic gears are used in certain aerospace applications, particularly in non-critical systems such as cabin equipment, small actuators, and control mechanisms. Their lightweight construction and noise reduction characteristics are advantageous in aerospace applications.

- Telecommunications: Plastic gears find applications in telecommunications equipment such as routers, switches, and communication devices. Their lightweight design, noise reduction properties, and cost-effectiveness make them suitable for these applications.

These are just a few examples of the industries that commonly use plastic gears. The versatility, cost-effectiveness, design flexibility, and specific performance characteristics of plastic gears make them valuable components in numerous applications across various sectors.

editor by CX 2024-04-04