Product Description

PRODUCT PARAMETER

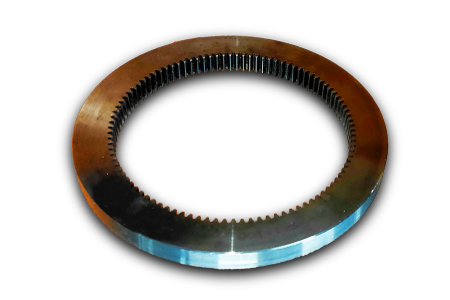

| China Transmission gear Main drive shaft gear ME58571 for CHINAMFG 4DR5 | ||||||

|

Part name |

Transmission shaft gear | |||||

|

Warranty |

1 Year |

|||||

|

HS Code |

||||||

|

Packing |

Carton Box with Brand / Nature Packing |

|||||

COMPANY INFORMATION

HangZhou CHINAMFG Imp.& Exp.Co .,Ltd located in HangZhou,ZHangZhoug Province. Have been committed to developing & supplying Auto Transmission Parts,putting ourselves to clients’ shoes to solve their demands.our company is mainly engaged in Auto Transmission Parts such as Transmission gearbox,Gear haft,Synchronizer ring,Cylinder Head and Differcial Assembly and so on.

With our honesty and credit, we sincerely hope to cooperate with you for greater development. Welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

WORLD-WIDE CUSTOMERS COMMENTS & FEEDBACK

Here is some of comments from our world-wide customers.

You can check all the comments at our company profile.

Please visit tashikomo

Click “company profile”,then choose “Rating & Reviews”

(please note: all our customer comments is real one………..)

We will package the product carefully and send it via EMS,DHL,or others…..

CONTACT

FAQ

★ What is your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent,

we can pack the goods in your branded boxes after getting your authorization letters.

★ What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages

before you pay the balance.

★Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Action now contact us for whole CATALOG.

MORE THEN 2000 KINDS OF OEM PARTS WAITTING FOR YHOU. PLEASE CONTACT US THE WHOLE CATALOG.

TRUST YOU WILL LIKE OUR DESIGNS & PRICE.

Please contat us for the WHOLE CATALOG. More than 2000 OEM PARTS.

WAITTING FOR YOU !!

ACTION NOW

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Warranty: | 1 Year |

|---|---|

| Type: | Shaft Gear |

| Material: | 20crmnti |

| Certification: | ISO |

| Automatic: | Manual |

| Standard: | Standard |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do you choose the right size ring gear for your application?

Choosing the right size ring gear for a specific application involves considering several factors related to the gear system, load requirements, space constraints, and performance objectives. Here’s a detailed explanation of the process involved in selecting the appropriate size ring gear:

- Determine the Gear System Parameters: Understand the specific requirements of the gear system in which the ring gear will be used. This includes identifying the input power, desired output speed, torque requirements, and operating conditions such as temperature, vibration, and lubrication.

- Calculate Gear Ratios: Determine the required gear ratios for the gear system. Gear ratios define the relationship between the rotational speeds and torques of the driving and driven gears. By knowing the desired gear ratios, you can calculate the appropriate size of the ring gear relative to the other gears in the system.

- Evaluate Load Capacity: Assess the load capacity needed for the application. Consider the maximum torque and radial loads that the ring gear will experience during operation. It’s crucial to select a ring gear that can handle the anticipated loads without excessive wear, deformation, or failure.

- Consider Space Limitations: Determine the available space for the ring gear within the application. Consider the overall dimensions, such as the outer diameter, inner diameter, and thickness of the ring gear. Ensure that the selected size fits within the designated space without interfering with other components or compromising the overall functionality of the system.

- Account for Manufacturing Considerations: Consider the manufacturability of the ring gear. Evaluate factors such as the feasibility of producing the required tooth profile, the availability of suitable materials, and the manufacturing capabilities of the supplier. It’s important to choose a size that can be efficiently manufactured while meeting the required quality standards.

- Consult Design Guidelines and Standards: Refer to industry design guidelines, standards, and specifications specific to the type of gear and application. These guidelines provide recommendations and formulas for calculating gear sizes based on factors such as tooth strength, contact stress, and bending stress. Adhering to recognized standards ensures that the selected ring gear size is appropriate for the intended application.

It is often beneficial to consult with gear design engineers or industry experts to ensure the proper selection of the ring gear size. They can provide detailed analysis, simulation, and expertise in choosing the optimal size based on the specific requirements and constraints of the application.

By carefully considering these factors and following established design practices, you can choose the right size ring gear that will deliver reliable performance, efficient power transmission, and long-term durability for your application.

\

How do you maintain and service a ring gear system?

Maintaining and servicing a ring gear system is crucial to ensure its optimal performance, reliability, and longevity. Here’s a detailed explanation of the maintenance and service procedures for a ring gear system:

- Regular Inspections: Conduct regular inspections of the ring gear system to detect any signs of wear, damage, misalignment, or abnormal conditions. Inspect the gear teeth for chips, cracks, or excessive wear. Check for proper gear engagement and backlash. Inspect the mounting bolts or fasteners for tightness. Regular inspections help identify potential issues early on and prevent further damage or failures.

- Cleaning and Lubrication: Clean the ring gear system periodically to remove dirt, debris, and old lubricant. Use appropriate cleaning methods and solvents that are compatible with the gear system materials. After cleaning, apply fresh lubricant according to the manufacturer’s recommendations. Ensure proper lubrication coverage and distribution to minimize friction, wear, and heat generation.

- Lubricant Analysis: Periodically analyze the condition of the lubricant in the ring gear system to assess its effectiveness and detect any contamination or degradation. Lubricant analysis involves collecting samples and sending them to a laboratory for testing. The analysis results can provide valuable information about the lubricant’s viscosity, contamination levels, and overall condition. Based on the analysis, determine whether lubricant replacement or additional maintenance actions are necessary.

- Bearing and Seal Inspection: If the ring gear system includes bearings or seals, inspect them regularly for wear, damage, or leaks. Check for excessive play, noise, or overheating in the bearings. Inspect the seals for proper sealing and lubricant retention. Replace any worn-out bearings or damaged seals to prevent further damage to the ring gear system.

- Torque Checks: Periodically check the torque of the mounting bolts or fasteners that secure the ring gear system. Over time, vibrations and operational stresses can cause bolts to loosen. Ensure that the bolts are tightened to the manufacturer’s recommended torque specifications. Perform torque checks during scheduled maintenance intervals or when any signs of loosening are observed.

- Alignment and Gear Meshing: Check and adjust the alignment of the ring gear system if necessary. Misalignment can lead to uneven wear, increased load on the gear teeth, and reduced performance. Ensure proper gear meshing and backlash according to the manufacturer’s specifications. Adjust the gear positioning or contact pattern if deemed necessary during inspections or maintenance activities.

- Repair or Replacement: If any significant damage, wear, or malfunction is identified during inspections or maintenance activities, plan for repair or replacement of the affected components. Depending on the severity and nature of the issue, repairs may involve repairing gear teeth, replacing damaged parts, or realigning the gear system. If extensive damage is present or the gear system has reached the end of its service life, consider replacing the entire ring gear system.

- Documentation and Record-Keeping: Maintain detailed documentation and records of all maintenance and service activities performed on the ring gear system. Keep track of inspection results, lubrication schedules, repairs, parts replacements, and any other relevant information. These records help establish a maintenance history, track performance trends, and provide valuable reference information for future maintenance and troubleshooting.

It’s important to note that the specific maintenance and service procedures may vary depending on the type of ring gear system, its application, and the manufacturer’s guidelines. Always refer to the manufacturer’s recommendations and consult with experts or professionals when necessary to ensure proper maintenance and servicing of the ring gear system.

How do ring gears differ from other types of gears?

Ring gears, also known as annular gears or internal gears, possess distinct characteristics that set them apart from other types of gears. Here’s a detailed explanation of how ring gears differ from other gears:

1. Tooth Configuration: The most significant difference between ring gears and other gears is their tooth configuration. In a ring gear, the teeth are located on the inside circumference of a circular ring, whereas in other gears such as spur gears, helical gears, and bevel gears, the teeth are present on the outer surface of the gear. This internal tooth arrangement makes ring gears unique and allows them to mesh with pinion gears or other external gears.

2. Gear Assembly: The assembly of ring gears differs from other gears. In most cases, ring gears are used in combination with pinion gears or other external gears. The pinion gear meshes with the teeth on the inside of the ring gear. This gear set configuration enables the transmission of rotational motion and torque.

3. Load Distribution: Ring gears distribute the load over a larger area compared to other types of gears. The load is spread across the internal teeth of the ring gear, resulting in improved load-carrying capacity and enhanced gear durability. This load distribution characteristic makes ring gears suitable for applications that involve high loads or continuous operation.

4. Gear Ratio: Ring gears offer specific advantages in terms of gear ratios. They are commonly used in applications where high gear ratios are required. The gear ratio is determined by the number of teeth on the ring gear compared to the number of teeth on the mating gear (such as a pinion gear). The internal tooth configuration of the ring gear allows for larger gear diameters, enabling higher gear ratios to be achieved.

5. Space Utilization: Ring gears provide a compact design compared to some other types of gears. The internal tooth arrangement allows for a more space-efficient gear assembly. This compactness is advantageous in applications where space is limited or where a high gear ratio needs to be achieved within a confined area.

6. Applications: Ring gears are commonly used in automotive transmissions, differential systems, planetary gear systems, industrial machinery, robotics, power generation equipment, and heavy machinery. Their unique characteristics make them suitable for applications that require precise motion control, load distribution, and high gear ratios.

It’s important to note that the specific design, tooth profile, material selection, and manufacturing techniques may vary for different types of gears, including ring gears. Each type of gear is designed to meet specific application requirements, operating conditions, and performance needs.

editor by CX 2024-01-10