Product Description

Key attributes

Other attributes

Applicable Industries

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Printing Shops, Construction works , Energy & Mining, Other, Advertising Company

Weight (KG)

1000

Showroom Location

None

Video outgoing-inspection

Provided

Machinery Test Report

Provided

Marketing Type

Hot Produc2571

Warranty of core components

3 months

Core Components

Gear

Place of Origin

ZheJiang , China

Condition

New

Warranty

6 Months

Shape

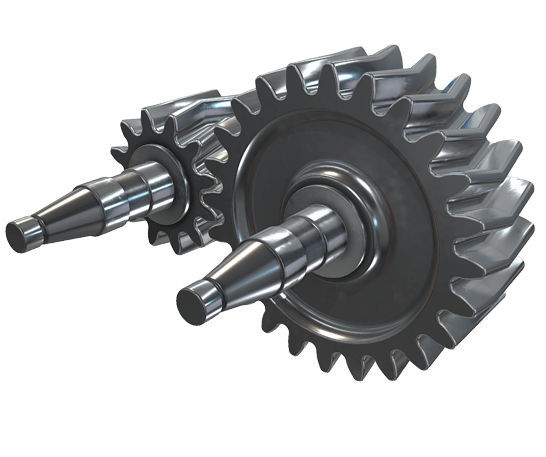

Spur

Brand Name

MSMT

Material

Steel

Surface treatment

OEM

Size

According to drawings

OEM

graphic design

Processing

Hobbing/Milling/Shapping

Packaging and delivery

Packaging Details

Packed and shipped according to customer requirements

Port

ZheJiang HangZhou

attribute-list

Supply Ability

5000 TONS per Month

Show less

Lead time

| Quantity (pieces) | 1 – 5 | > 5 |

| Lead time (days) | 45 | To be negotiated |

OUR FACTORY

OUR WORKSHOP

OUR WAREHOUSE

WORK SHOP

EQUIPMENTS

PACKING & DELIVERY

Packing Details : Wooden box with fumigation or Wooden Fram

Delivery Details : 30~60days or Based on the quantity

FAQ

FAQ

Q1.Are you a factory or trading company?

A:We are a factory trading company, the factory has been established for 30 years.Strict quality control of production processes

and tolerances.Manufacture products according to your drawings or specifications.

Q2: How to choose the products that meet our requirements?

A2: Tell me the information of the product, or provide the relevant parameter diagram of the product, or give me some clear photos

of the product and related equipment. I would be grateful if you could tell me the type of product you initially used.

Q3:What is the quality of your products?

A3:Quality is always the foundation of our company, I suggest you buy samples to evaluate the quality. Mech Sien (HangZhou)

Machinery Technology Co., Ltd has been engaged in R&D, design and production for more than 30 years.

Q4. How long does the delivery period take?

A4: Generally speaking, we have a lot of regular standard products in stock, if stock is low, it takes 10-15 days, and customized

products take longer. Delivery time takes 20-45 days, but we are very flexible depending on the specific order.

Q5: Can you do OEM / ODM orders?

A5: Yes,we have rich experience on OEM/ODM order and like CHINAMFG Non-disclosure Agreement before sample making

| After-sales Service: | 24 Hours Online and Offline Service |

|---|---|

| Warranty: | 1 Year |

| Certification: | ISO9001: 2000 |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do you choose the right size herringbone gear for your application?

Choosing the right size herringbone gear for your application involves considering several factors and performing engineering calculations. Here’s a detailed explanation of the steps involved in selecting the appropriate size herringbone gear:

- Determine the Application Requirements: Start by understanding the specific requirements of your application. Consider factors such as the input and output speeds, torque loads, power requirements, duty cycle, and operating conditions. Determine the desired service life, efficiency, and reliability expectations for the gear system.

- Calculate the Gear Ratios: Determine the required gear ratios based on the speed and torque requirements of your application. Gear ratios define the relationship between the rotational speeds and torques of the input and output shafts. Select appropriate gear ratios that fulfill the desired performance objectives.

- Calculate the Load and Torque: Estimate the maximum load and torque that the herringbone gear will experience during operation. Consider both static and dynamic loads, shock loads, and any potential overload conditions. Calculate the required torque capacity of the gear system based on these load considerations.

- Consider the Size and Space Constraints: Evaluate the available space and size constraints in your application. Measure the available distance for gear installation, including the gear’s diameter, width, and axial length. Consider any restrictions on the gear’s physical dimensions and ensure that the selected gear size fits within the available space.

- Determine the Gear Module: The gear module is a parameter that defines the size and number of gear teeth. Calculate the gear module based on the desired gear ratios, torque capacity, and available space. The gear module is typically determined by considering a balance between gear tooth strength, contact ratio, and manufacturing feasibility.

- Perform Gear Design Calculations: Utilize standard gear design formulas and calculations to determine the required number of gear teeth, pitch diameter, helix angles, and other gear dimensions. Consider factors such as gear tooth strength, contact ratio, tooth profile optimization, and gear manufacturing standards. These calculations ensure that the selected gear size can handle the anticipated loads and provide reliable performance.

- Consult Manufacturers and Standards: Consult gear manufacturers, industry standards, and guidelines to ensure compliance with best practices and safety requirements. Manufacturers can provide technical expertise, recommend suitable gear sizes, and offer guidance on material selection, heat treatment processes, and gear quality standards.

- Consider Cost and Availability: Evaluate the cost implications and availability of the selected gear size. Consider factors such as material costs, manufacturing complexity, lead times, and the overall economic feasibility of the gear system. Balance the desired performance with cost considerations to arrive at an optimal gear size.

It’s important to note that selecting the right size herringbone gear requires expertise in gear design and engineering. If you lack the necessary knowledge, it is advisable to consult with experienced gear engineers or manufacturers who can assist in the selection process.

In summary, choosing the right size herringbone gear involves determining the application requirements, calculating gear ratios and torque loads, considering size constraints, determining the gear module, performing gear design calculations, consulting manufacturers and standards, and considering cost and availability. Following these steps ensures that the selected herringbone gear size meets the specific needs of your application and provides reliable and efficient operation.

Are herringbone gears suitable for high-torque applications?

Herringbone gears are well-suited for high-torque applications due to their design characteristics and advantages. Here’s a detailed explanation of why herringbone gears are suitable for high-torque applications:

- Large Surface Area of Contact: Herringbone gears have a larger surface area of contact between the gear teeth compared to conventional spur gears. This increased contact area allows herringbone gears to distribute the torque load more effectively. The larger contact area helps prevent tooth deflection and distributes the load across a greater number of teeth, resulting in improved torque transmission capabilities.

- Higher Torque Capacity: The design of herringbone gears enables them to handle higher torque loads. The opposing helix angles of the teeth in herringbone gears cancel out the axial thrust, which is generated during gear meshing. This cancellation of axial thrust allows herringbone gears to transmit higher torque without the need for additional thrust bearings or mechanisms. The increased torque capacity of herringbone gears makes them suitable for demanding applications that require high torque transfer.

- Reduced Gear Tooth Deflection: Herringbone gears exhibit reduced tooth deflection compared to spur gears. The double helical arrangement of the teeth in herringbone gears helps counteract the bending forces that can cause tooth deflection. This characteristic allows herringbone gears to maintain a more precise gear mesh, even under high torque loads. The reduced tooth deflection enhances the overall performance and reliability of herringbone gears in high-torque applications.

- Compact Gearbox Design: The high torque capacity of herringbone gears enables the design of more compact gearboxes. The ability to transmit higher torque loads in a smaller package can be advantageous in applications where space is limited. The compact design not only saves space but also reduces the overall weight of the system, making herringbone gears suitable for high-torque applications with size and weight constraints.

- Smooth Operation: Herringbone gears provide smooth and precise gear engagement, even under high-torque conditions. The opposing helix angles of the teeth facilitate gradual meshing and unmeshing, reducing impact and shock loads. The smooth operation minimizes vibrations and noise, which is particularly important in high-torque applications where excessive vibrations can lead to premature wear or component failure.

While herringbone gears offer several advantages for high-torque applications, it’s important to consider other factors such as lubrication, gear material, and system design. Proper lubrication and the use of high-strength materials can further enhance the performance and durability of herringbone gears in high-torque applications. Additionally, system design considerations, such as proper alignment, stiffness, and maintenance practices, should be taken into account to ensure optimal performance and longevity of herringbone gears in high-torque scenarios.

How do herringbone gears differ from other types of gears?

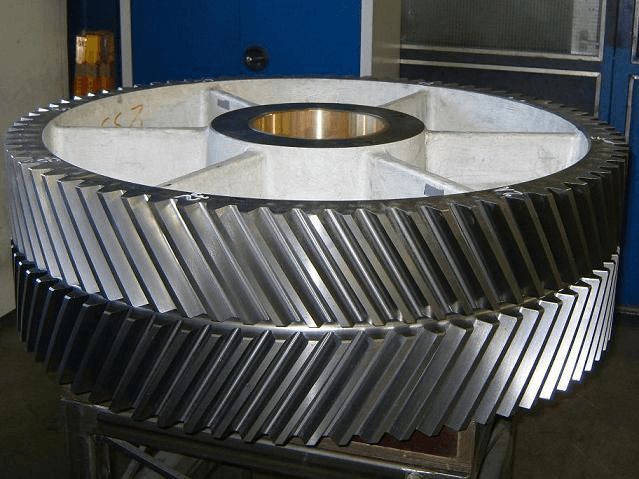

Herringbone gears, also known as double helical gears, possess distinct characteristics that set them apart from other types of gears. Here’s a detailed explanation of how herringbone gears differ from other gears:

1. Tooth Design: Herringbone gears have a unique V-shaped or herringbone-shaped tooth profile. This design is formed by two helical gear sections that are mirror images of each other. In contrast, other gears, such as spur gears, helical gears, bevel gears, or worm gears, have different tooth profiles and configurations.

2. Axial Thrust Elimination: One of the key differentiating factors of herringbone gears is their ability to eliminate or greatly reduce axial thrust forces. In helical gears, the helix angle of the teeth generates an axial force during rotation, requiring the use of thrust bearings to counteract the thrust loads. Herringbone gears, with their double helix design, have opposing helix angles that cancel out the axial forces, eliminating the need for thrust bearings.

3. Noisy Cancellation: Herringbone gears are known for their noise-canceling properties. The opposing helix angles of the two gear sections help reduce vibrations and noise during operation. This is particularly beneficial in applications where noise reduction is critical, such as printing presses or precision machinery.

4. Increased Load Capacity: The V-shaped tooth profile of herringbone gears provides increased tooth contact area compared to other gears with straight or helical teeth. This increased contact area improves load distribution and allows herringbone gears to handle higher torque loads, resulting in an increased load-carrying capacity.

5. Bidirectional Power Transmission: Herringbone gears are designed to transmit power bidirectionally. The symmetrical tooth profiles of herringbone gears enable power transmission in both directions, making them suitable for applications where reversing or bidirectional power transfer is required.

6. Smooth Operation: Due to their double helix design, herringbone gears provide smooth and gradual tooth engagement. This gradual meshing reduces sliding friction, minimizes backlash, and ensures a continuous transfer of power. This characteristic makes herringbone gears desirable in applications where smooth operation and high efficiency are crucial.

7. Complex Manufacturing: Herringbone gears have a more complex manufacturing process compared to some other gear types. The creation of the herringbone tooth profile requires specific machining techniques and precision to ensure proper meshing and alignment of the gear sections.

It’s important to note that the selection of gear type depends on the specific requirements of the application. While herringbone gears offer unique advantages, other gear types may be more suitable in certain scenarios based on factors such as space limitations, cost, torque requirements, and operating conditions.

In summary, herringbone gears stand out with their distinctive tooth design, axial thrust elimination, noise-canceling properties, increased load capacity, bidirectional power transmission, smooth operation, and complex manufacturing process, making them well-suited for various industrial applications.

editor by CX 2023-11-14