Product Description

Product Description

|

Technology |

Powder Metallurgy |

Metal injection moding |

|

General Material |

Fc5718/Fn5718 |

17-4Ph/4605 |

|

Density |

6.7-6.8 |

7.7-7.8 |

|

Hardness |

Fc5718(20-30HRC) Fn5718(35-40HRC) |

17-4Ph(35-40HRC) 4605(45-50HRC) |

|

Application |

Medical apparatus and instruments Hardware field Automobile industry Home appliances |

|

Main Advantages

1) Powder metallurgy can ensure the accuracy and uniformity of the material composition ratio.

2) Suitable for producing products of the same shape and large quantities, low production cost.

3) The production process is not afraid of oxidation, and no material pollution will occur.

4) No subsequent machining processing is required, saving materials and reducing costs.

5) Most difficult metals and compounds, pseudo alloys, porous materials can only be manufactured by powder metallurgy

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory and trading company

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

| Application: | Machinery, Agricultural Machinery |

|---|---|

| Hardness: | Soft Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Cast Steel |

| Customization: |

Available

| Customized Request |

|---|

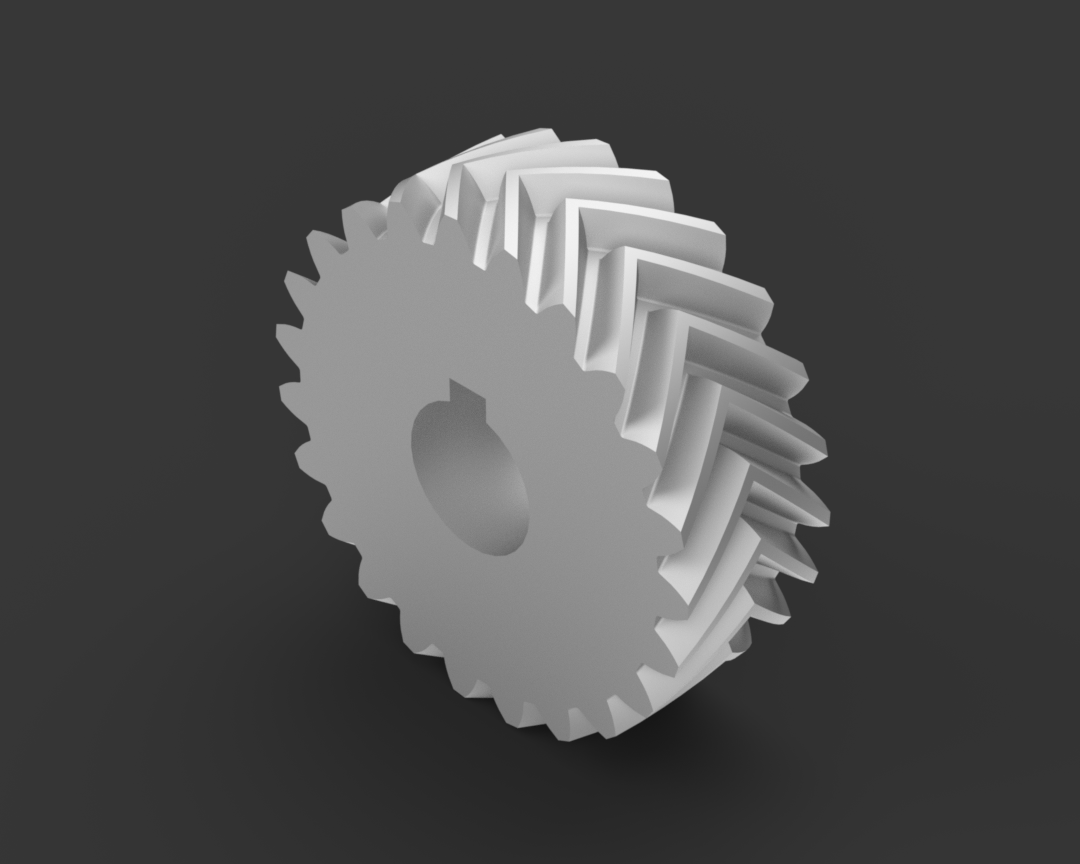

How do herringbone gears contribute to smooth power transmission?

Herringbone gears contribute to smooth power transmission through their unique design and characteristics. Here’s a detailed explanation of how herringbone gears achieve smooth power transmission:

- Opposing Helix Angles: Herringbone gears have a double helical tooth profile with opposing helix angles on each side. The helix angles are inclined in opposite directions to each other. This design feature helps to cancel out axial and radial forces that would occur in single helical gears. The opposing helix angles create a self-centering effect that promotes proper tooth engagement and load distribution, reducing gear vibrations and ensuring smooth power transmission.

- Reduced Vibration and Noise: The opposing helix angles of the herringbone gear teeth minimize gear vibrations during operation. When the teeth of one side of the gear mesh with the teeth of the other side, the opposing helix angles create a balanced force distribution that counteracts any tendency for the gear to move laterally. This results in reduced vibration and noise levels, making herringbone gears ideal for applications where quiet operation is desired, such as precision machinery and automotive transmissions.

- Large Contact Area: Herringbone gears have a larger contact area compared to spur gears. The double helical tooth profile allows for overlapping engagement of the gear teeth, resulting in a larger contact ratio. This increased contact area distributes the transmitted torque over more teeth, reducing the stress on individual teeth and promoting smoother power transmission. The larger contact area also helps to minimize wear and improve the overall durability of the gear system.

- Enhanced Load Distribution: The double helical tooth design of herringbone gears provides improved load distribution along the tooth surfaces. The opposing helix angles help to evenly distribute the transmitted load between the two sides of the gear. This balanced load distribution minimizes localized stress concentrations and reduces the risk of tooth failure. It ensures that the torque is transmitted smoothly across the entire tooth profile, resulting in efficient power transmission and reduced wear.

- Efficient Torque Transfer: Herringbone gears offer efficient torque transfer due to their large contact area and overlapping tooth engagement. The double helical tooth profile provides a larger contact ratio compared to spur gears, allowing for a greater number of teeth in contact at any given time. This increased contact ratio distributes the torque more evenly, reducing the risk of tooth shear and improving power transmission efficiency. The efficient torque transfer contributes to smooth and reliable operation of the gear system.

These factors combined – opposing helix angles, reduced vibration and noise, large contact area, enhanced load distribution, and efficient torque transfer – contribute to the smooth power transmission capabilities of herringbone gears. Their design minimizes the effects of axial and radial forces, promotes balanced load distribution, and ensures reliable and efficient power transfer in various applications.

How do you maintain and service a herringbone gear system?

Maintaining and servicing a herringbone gear system is crucial for ensuring its optimal performance, longevity, and reliability. Regular maintenance and service activities help identify and address potential issues, minimize wear, and extend the lifespan of the gear system. Here’s a detailed explanation of how to maintain and service a herringbone gear system:

- Inspection: Conduct regular visual inspections of the gear system to identify any signs of wear, damage, or misalignment. Inspect the gear teeth, shafts, bearings, and other components for any visible abnormalities, such as pitting, scoring, cracks, or excessive wear. Check for oil leaks, loose fasteners, or any other potential issues that may affect the gear system’s performance.

- Lubrication: Ensure that the lubrication of the herringbone gear system is adequate and meets the manufacturer’s recommendations. Monitor the lubricant level and condition regularly. Check for proper lubricant distribution and coverage on the gear teeth and contact surfaces. Replenish or replace the lubricant as necessary to maintain the required film thickness and lubricating properties.

- Alignment and Clearance: Check and maintain proper shaft alignment to prevent misalignment-related issues. Use alignment tools such as dial indicators or laser alignment systems to verify the parallelism and concentricity of the gear system shafts. Ensure that the gear engagement is correct and that there is appropriate gear backlash. Make any necessary adjustments to optimize gear alignment and clearance as per the manufacturer’s guidelines.

- Fasteners and Connections: Regularly inspect and tighten all fasteners, such as bolts, set screws, or clamps, to ensure that they are securely fastened. Loose fasteners can lead to misalignment, vibration, and potential gear system failure. Follow the recommended torque specifications provided by the manufacturer when tightening the fasteners to avoid over-tightening or under-tightening.

- Monitoring and Analysis: Implement a monitoring and analysis program to track the performance of the herringbone gear system over time. This can include vibration analysis, temperature monitoring, and oil analysis. These techniques can help identify any abnormal conditions, such as excessive vibration, increased temperatures, or the presence of contaminants or wear particles in the lubricant. Regular analysis and monitoring can aid in detecting potential issues early and taking appropriate corrective actions.

- Repair and Replacement: If any signs of wear, damage, or abnormal conditions are detected during inspections or monitoring, take prompt action to address the issues. Depending on the severity of the problem, this may involve repairing or replacing worn or damaged components, such as gear teeth, bearings, or seals. Follow the manufacturer’s guidelines and consult with qualified technicians or professionals for any necessary repair or replacement procedures.

- Documentation and Record-keeping: Maintain accurate documentation and records of all maintenance and service activities performed on the herringbone gear system. This includes inspection reports, lubrication records, repair or replacement history, and any other relevant information. These records can serve as a reference for future maintenance, help track the gear system’s performance, and aid in troubleshooting or warranty claims if needed.

It is important to note that the specific maintenance and service requirements may vary depending on the gear system design, application, and operating conditions. Always refer to the manufacturer’s guidelines, technical documentation, and any applicable industry standards for the recommended maintenance practices and service intervals specific to your herringbone gear system.

What industries commonly use herringbone gears?

Herringbone gears, also known as double helical gears, are utilized in various industries due to their unique design and advantageous characteristics. Here’s a detailed explanation of the industries that commonly use herringbone gears:

- Power Generation and Transmission: Herringbone gears find extensive use in power generation and transmission systems. They are employed in gearboxes, drivetrains, and speed reducers that are essential components in power plants, including thermal power plants, hydroelectric power plants, and wind farms. Herringbone gears provide efficient torque transfer and smooth operation, making them suitable for power generation applications.

- Heavy Machinery and Equipment: Herringbone gears are widely employed in heavy machinery and equipment across different industries. Applications include construction machinery, mining equipment, industrial machinery, and material handling systems. These gears can handle high loads and provide reliable torque transmission, making them suitable for heavy-duty operations.

- Oil and Gas Industry: The oil and gas industry extensively utilizes herringbone gears in various equipment. They are found in pumps, compressors, turbines, and other machinery used in oil refineries, petrochemical plants, and offshore platforms. Herringbone gears are capable of handling high torque requirements and provide reliable performance in demanding and critical environments.

- Marine and Shipbuilding: Herringbone gears are widely used in marine propulsion systems, including ship propulsion drives and propeller shaft arrangements. They are also found in other marine equipment, such as winches, cranes, and offshore drilling rigs. Herringbone gears facilitate efficient power transfer and contribute to the smooth and reliable operation of marine vessels.

- Aerospace and Aviation: Herringbone gears are employed in aerospace and aviation applications where high-speed and high-torque transmission is required. They are used in aircraft engines, landing gear systems, and helicopter transmissions. Herringbone gears contribute to the efficient and reliable performance of aerospace and aviation systems.

- Automotive and Transportation: Herringbone gears are utilized in various automotive applications that require high torque and smooth power transmission. They are found in automotive transmissions, differential gears, and drivetrain systems. Herringbone gears enable efficient power transfer and contribute to the overall performance and reliability of vehicles.

- Printing and Packaging: Herringbone gears are commonly used in printing presses and packaging machinery. They are employed in the transmission systems that drive the rollers, cylinders, and cutting mechanisms, ensuring precise and synchronized operation. Herringbone gears’ noise-canceling properties and smooth engagement make them desirable in printing and packaging applications that require high precision and quality.

- Steel and Metalworking: Herringbone gears are utilized in steel mills and metalworking machinery. They are found in rolling mills, extruders, forge presses, and other equipment involved in metal processing and shaping. Herringbone gears withstand the high loads, vibrations, and harsh operating conditions commonly encountered in steel and metalworking industries.

- Railway and Transportation Systems: Herringbone gears are employed in railway systems, particularly in locomotives and rolling stock. They are used in propulsion systems, gearboxes, and drivetrains, ensuring efficient power transmission and reliable train operation. Herringbone gears contribute to the smooth and safe movement of trains.

These are just a few examples of the industries that commonly use herringbone gears. Their unique tooth design, load-carrying capacity, bidirectional power transmission capability, and smooth operation make them suitable for a wide range of industrial applications that require efficient and reliable torque transmission.

editor by CX 2023-11-01