Product Description

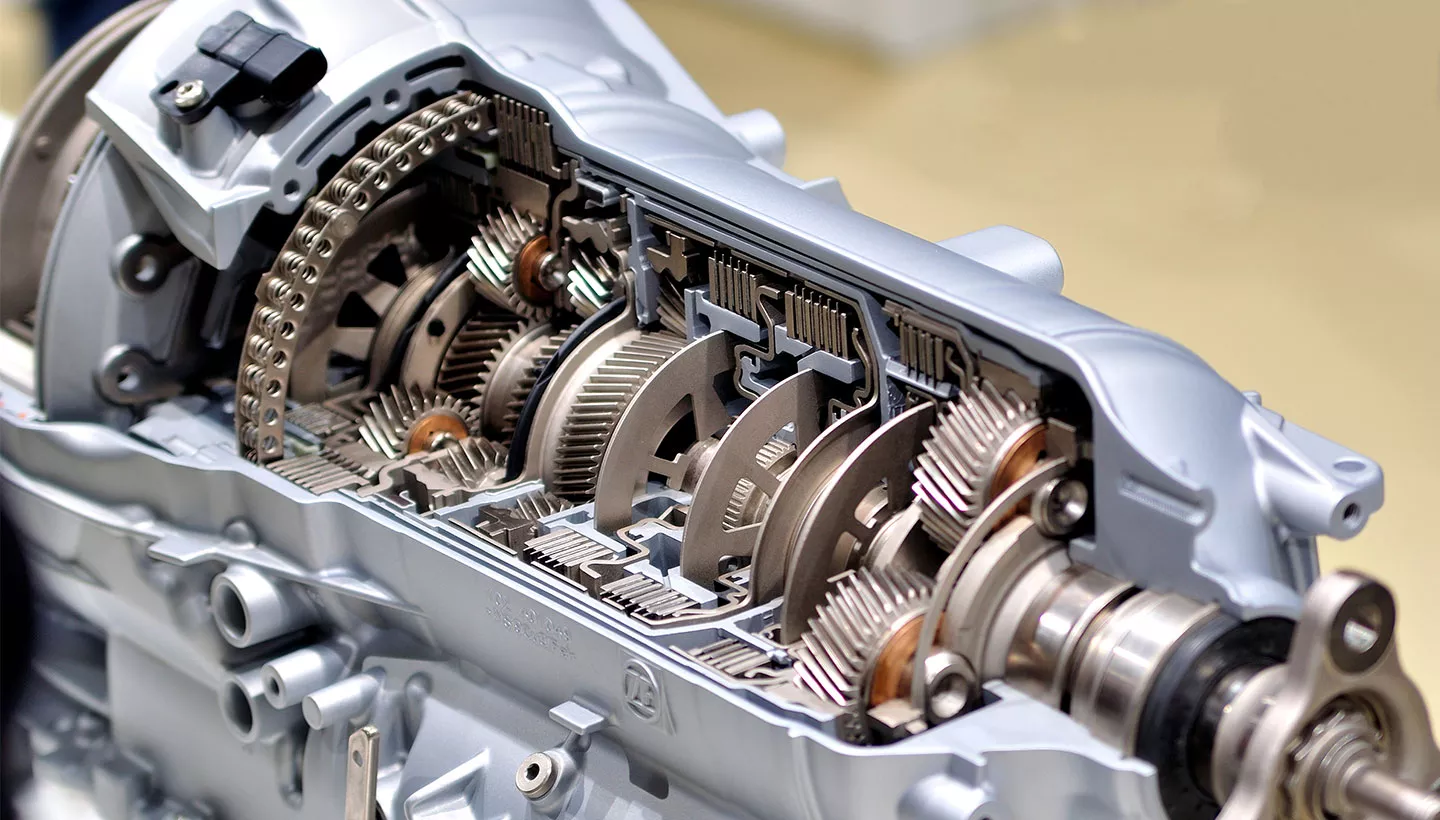

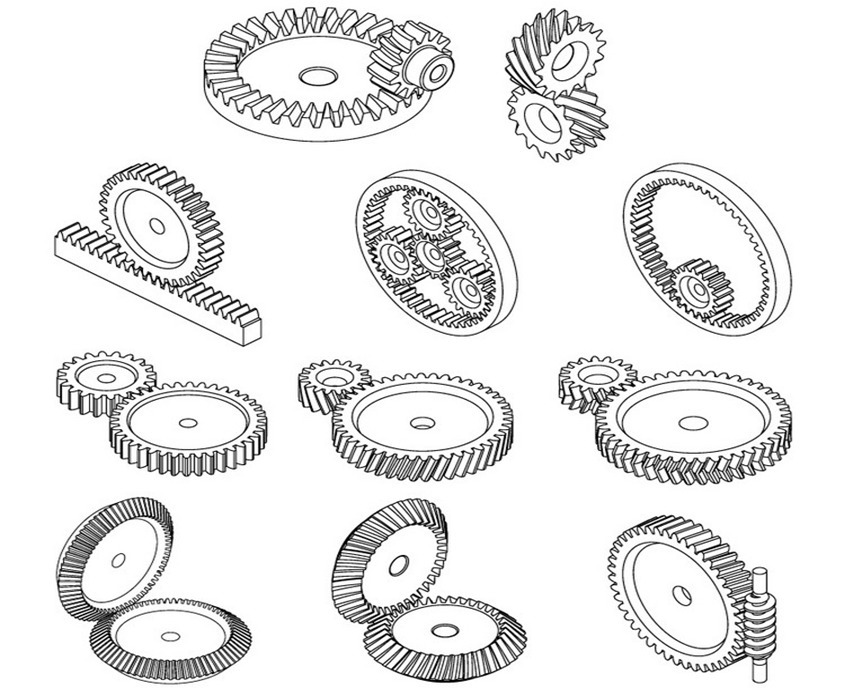

Customized High Precision Forging Machining Steel Gears for Automobile Gearbox

|

Material |

S45C steel, Stainless steel 304, Plastic, Brass, 42CrMo,20CrMnTi and so on |

|||

|

Heat treatment |

Hardening and Tempering, High Frequency Quenching,Carburizing etc |

|||

|

Surface treatment |

Blacking, Polishing, Anodization, Chrome Plating, Zinc Plating, Nickel Plating |

|||

|

Application |

Precision cutting machines. Lathes. Milling machines. Grinders. Automated mechanical systems. Automated warehousing systems. |

|||

|

Machining process: |

Hobbing, Milling, Drilling, Shaving, Grinding |

|||

1. Type: spur gear, helical gear, bevel gear, worm gear, ring gear etc.

2. Material: carbon steel, alloy steel, stainless steel, nylon, POM , plastic

3. Treatment: teeth hardened, zinc, quenching, black oxide, color zinc

4. OEM & Standard:Standard size according to the catalog.OEM size, hub, hole, keyway and

set screw, all can produce according to your drawing.

5. Gear drive advantages:High transmission accuracy, high transmission efficiency, reliable work

and long service life.

Our Service:

1. Competitive price

2. High quality products

3. OEM service

4. 24 hours online service

5. Professional technical service

6. Sample available

1. We are a professional manufacturer specializing in manufacturing various metal parts, including

CNC precision automatic lathe machined parts, automatic lathe parts, milling machined parts, wire

cutting machined parts etc.

2.With experienced technical engineers and modern inspection equipment, our factory can help you to

lower cost at the moment of worldwide financial crisis.

3.We are committed to focusing on the client’s demand and satisfaction, and to providing high quality

products at competitive prices according to your drawings or samples. Special parts for your special

needs!

4.Our strong R&D and QC department can control the products to meet your strict requirment, 100%

inspection on critical dimensions with high accuracy +/-0.01-0.005mm.

5.We are committed to focusing on the client’s demand and satisfaction, and to providing high quality

products at competitive prices according to your drawings or samples. Special parts for your special

needs!

6.Although the business has become more difficult since competition increased, our products have

sold well in recent years. As a matter of fact, our parts are being exported to more than 10 countries

and regions. And they’re always received favourably.

Our Main Product:

1. Gear and Rack

2. Ball Screw and Nut

3. Linear Xihu (West Lake) Dis. and Block

4. Sprocket and Roller Chain

5. Timing Pulley and Timing Belt

Application

Gear can be used on many machines,like lathe machine, cutting machine, cnc machine and engraving

machine etc; It can also be used in many fields, machinery, construction, building, manufacturing,

industrial etc.

Package

Usually we wrap the gears with bubble wrap, then put the gears in a carton, and finally seal the

carton tightly.We can also make the package according to customers’ demands.

FAQs

Q: Are you factory or trading company?

A:Truly we are a factory over 15 years. We located in HangZhou City, ZheJiang Province, near

HangZhou port.

Q: What is your production range?

A: Gears, impellers, shaft; shaft couplings; end cover; cnc machining parts,etc.

Q: How long can I get some samples for checking and what about the price?

A: Normaly samples will be done within 3-5 days.

The sample cost depends on the information (size, material, finish, etc.).

We will return the sample cost when you place order.

Q:How is the warranty of the products quality control?

A:We hold the tightend quality controlling from very begining to the end and aim at 100% error free.

Q:How to get an accurate quotation?

A:If you are interested in our products, please provide us with below information:

If there is something you are demanding or interested, please feel free to contact with

us, we will feedback within 12 hours.

| After-sales Service: | as Per Your Specification |

|---|---|

| Warranty: | 6 Months |

| Condition: | New |

| Samples: |

US$ 15/Piece

1 Piece(Min.Order) | Order Sample Samples produced according to customer′s drawing

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does a synchronized transmission system operate in manual cars?

A synchronized transmission system is a key component of manual transmissions in cars. Here’s a detailed explanation:

1. Purpose of Synchronized Transmission:

The purpose of a synchronized transmission system is to facilitate smooth and effortless shifting between gears in a manual transmission. It ensures that the rotational speeds of the input shaft (connected to the engine) and the output shaft (connected to the wheels) match before engaging the selected gear.

2. Synchronizer Rings:

The synchronized transmission system utilizes synchronizer rings, also known as synchro rings or blockers, to achieve synchronization. These rings are mounted on the transmission’s main shaft and are responsible for equalizing rotational speeds between the input and output shafts.

3. Cone Clutch Design:

The synchronizer rings feature a cone clutch design. When the driver selects a gear using the gear lever, the synchro ring corresponding to that gear slides over the gear’s dog teeth on the output shaft. The synchro ring and the dog teeth have matching cone-shaped surfaces.

4. Friction and Synchronization:

As the synchro ring engages with the dog teeth, it creates friction between the cone surfaces. This friction helps equalize the speeds of the input and output shafts. The synchro ring synchronizes the rotational speeds of the selected gear and the output shaft, allowing for smooth gear engagement.

5. Blocking and Engagement:

Once the rotational speeds are synchronized, the driver can easily engage the selected gear by pressing the clutch pedal and shifting the gear lever. The synchro rings facilitate the engagement by temporarily blocking the dog teeth on the output shaft, allowing the gears to mesh smoothly without grinding or clashing.

6. Double-Clutching:

In some older manual transmissions or vehicles with non-synchronized transmissions, a technique called double-clutching is required for smooth gear engagement. Double-clutching involves an additional step of disengaging the clutch after shifting out of the current gear, briefly engaging the clutch to match the engine speed with the transmission speed, and then shifting into the desired gear while the clutch is disengaged again. This technique is not necessary in modern synchronized transmissions.

7. Benefits of Synchronized Transmission:

The synchronized transmission system offers several benefits, including:

- Smooth shifting: The synchronizer rings enable seamless and smooth gear shifts, enhancing the overall driving experience.

- Reduced wear and tear: By equalizing rotational speeds before gear engagement, the synchronized transmission system minimizes wear and tear on the gears, synchro rings, and other transmission components.

- User-friendly operation: Synchronized transmissions are user-friendly, allowing drivers to shift gears effortlessly without the need for complex techniques like double-clutching.

In summary, a synchronized transmission system in manual cars utilizes synchronizer rings with cone clutch design to synchronize the rotational speeds of the input and output shafts. This enables smooth gear engagement and seamless shifting between gears, providing a user-friendly and efficient driving experience.

What is the impact of gear selection on fuel efficiency in a car?

Gear selection in a car has a significant impact on fuel efficiency. Here’s a detailed explanation:

1. Optimal Engine Speed:

Choosing the right gear allows the engine to operate at its optimal speed or within its “power band.” Each engine has a range of RPM (revolutions per minute) where it delivers the best balance of power and fuel efficiency. By selecting the appropriate gear, the engine can stay within this range, maximizing fuel efficiency.

2. Engine Load:

Gear selection affects the load on the engine. Higher gears, such as fifth or sixth gear, provide a higher gear ratio, reducing the engine’s rotational speed for a given vehicle speed. This reduces the load on the engine and can improve fuel efficiency, especially during highway driving where maintaining a steady speed is common.

3. Avoiding Over-Revving:

Shifting to a higher gear at the right time helps prevent the engine from over-revving. Over-revving occurs when the engine operates at excessively high RPM, which can waste fuel and potentially cause engine damage. By upshifting in a timely manner, the engine can run at a more efficient RPM range, leading to better fuel economy.

4. Acceleration and Deceleration:

The choice of gear during acceleration and deceleration also affects fuel efficiency. During acceleration, shifting up to higher gears smoothly and at appropriate RPM levels promotes fuel efficiency. Similarly, when decelerating, downshifting to lower gears while utilizing engine braking can save fuel by reducing the need for excessive braking and maintaining better control over vehicle speed.

5. Driving Conditions:

The impact of gear selection on fuel efficiency can vary based on driving conditions. For example, in hilly or mountainous terrains, downshifting to lower gears on uphill climbs can provide the necessary power while avoiding excessive fuel consumption. In stop-and-go city traffic, selecting lower gears can aid in smoother acceleration from a standstill, reducing fuel waste.

6. Manual vs. Automatic Transmissions:

The impact of gear selection on fuel efficiency can differ between manual and automatic transmissions. Manual transmissions offer more control over gear selection, allowing drivers to optimize fuel efficiency by choosing the most suitable gear for a given situation. On the other hand, modern automatic transmissions are designed to optimize fuel efficiency by automatically selecting the appropriate gear based on driving conditions and engine load.

In summary, gear selection plays a crucial role in determining fuel efficiency in a car. Optimal gear selection helps keep the engine operating at its most efficient RPM range, reduces engine load, prevents over-revving, and promotes smoother acceleration and deceleration. By understanding the relationship between gear selection and fuel efficiency, drivers can adopt driving habits that maximize fuel economy and reduce fuel consumption.

What are the common types of automobile transmissions available?

There are several common types of automobile transmissions used in vehicles. Here’s a detailed explanation:

1. Manual Transmission: Manual transmissions, also known as “stick shift” or “standard” transmissions, require the driver to manually shift gears using a clutch pedal and gearshift lever. They typically have a set of forward gears, including first, second, third, fourth, and fifth (or sixth) gears, along with a reverse gear. Manual transmissions offer direct control over gear selection and are often preferred by enthusiasts for their engagement and control.

2. Automatic Transmission: Automatic transmissions use a torque converter and a complex system of planetary gears to automatically shift gears without driver intervention. They are the most common type of transmission in modern vehicles. Automatic transmissions provide smooth and convenient operation as they automatically select the appropriate gear ratio based on factors such as vehicle speed, engine load, and driver input. They typically offer “Drive” (D) mode for normal driving and may include additional modes like “Sport” (S) or “Economy” (E) for different driving preferences.

3. Continuously Variable Transmission (CVT): CVT is a type of automatic transmission that offers an infinite number of gear ratios within a specific range. Instead of using traditional gears, CVTs use a system of belts or chains and pulleys to provide seamless gear ratio changes. CVTs are known for their smoothness and fuel efficiency as they keep the engine operating at its most efficient RPM. They are commonly found in smaller vehicles and hybrid cars.

4. Dual-Clutch Transmission (DCT): DCT combines features of both manual and automatic transmissions. It uses two separate clutches for odd and even gears, allowing for quick and smooth gear shifts without interrupting power delivery. One clutch handles the current gear, while the other anticipates and prepares the next gear for engagement. DCTs provide fast and precise gear changes, making them popular in high-performance and sporty vehicles.

5. Automated Manual Transmission (AMT): AMT, also known as “Semi-Automatic Transmission” or “Clutchless Manual Transmission,” is essentially a manual transmission with automated clutch and gear shifting. Unlike traditional automatic transmissions, AMTs do not have a torque converter. Instead, they use actuators to control the clutch and gear selection based on the driver’s input or pre-programmed settings. AMTs are cost-effective alternatives to conventional automatic transmissions and are commonly found in entry-level or budget-friendly vehicles.

6. Sequential Manual Transmission (SMG) and Dual-Clutch Sequential Transmission: Sequential transmissions are commonly used in high-performance and racing vehicles. They allow for quick and precise sequential gear shifting without the need for a clutch pedal. SMGs use a single clutch, while dual-clutch sequential transmissions operate similarly to DCTs, with two clutches for improved performance and faster gear changes. Sequential transmissions provide rapid gear shifts, enhanced control, and are often controlled via paddle shifters mounted on the steering wheel.

These are some of the most common types of automobile transmissions available. Each type has its own advantages and characteristics, catering to different driving preferences, performance requirements, and fuel efficiency goals.

editor by CX 2023-10-31